In the ever-evolving world of manufacturing, efficiency and flexibility are paramount. To meet these demands, industries continuously seek innovative solutions that streamline processes while maintaining high standards of quality and safety. One such solution gaining prominence is the Aluminum Profile Lean Pipe System. This versatile system merges the strengths of traditional lean manufacturing principles with the robustness of aluminum, offering a dynamic approach to enhancing operational efficiency.

What is an Aluminum Profile Lean Pipe System?

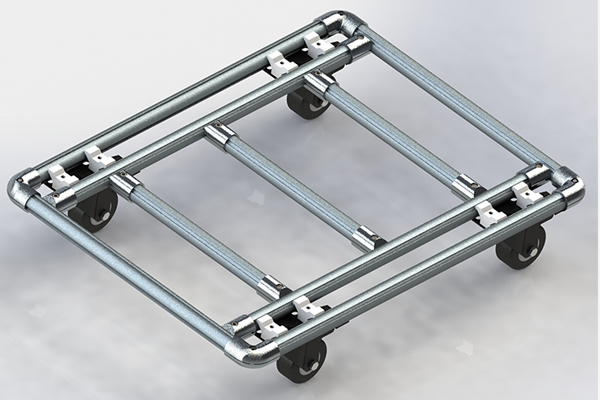

An Aluminum Profile Lean Pipe System is a modular assembly system composed of aluminum pipes and connectors. These systems are designed to create customized and adaptable structures such as workstations, racks, trolleys, and shelving units. Unlike conventional steel systems, aluminum profiles are lightweight, corrosion-resistant, and highly customizable, making them ideal for a wide range of applications in various industries.

Key Components of the System

- 1. Aluminum Pipes and Profiles: These form the backbone of the system. Available in various diameters and cross-sectional shapes, they provide the structural integrity required for building durable and stable assemblies.

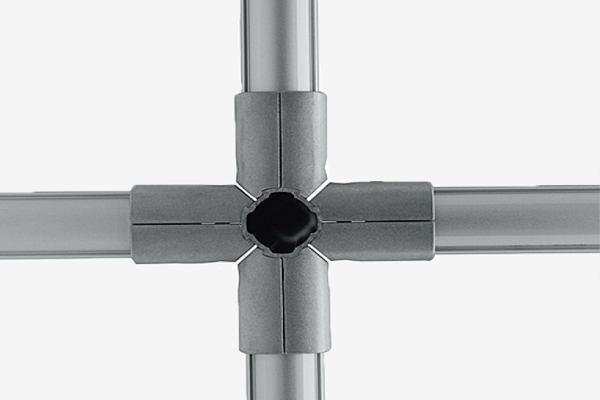

- 2. Connectors and Joints: These are crucial for assembling the aluminum pipes into functional structures. The connectors are typically made from high-strength materials and are designed to offer flexibility in assembly, allowing for quick modifications and adjustments.

- 3. Accessories and Fittings: To enhance the functionality of the system, a wide range of accessories such as wheels, shelves, hooks, and brackets are available. These fittings enable the creation of highly specialized and efficient workspaces.

Advantages of Aluminum Profile Lean Pipe Systems

- 1. Lightweight and Durable: Aluminum profiles are significantly lighter than their steel counterparts, reducing the overall weight of the structures. This not only makes them easier to handle and assemble but also enhances mobility, particularly for applications involving trolleys and mobile workstations.

- 2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents rusting, making it an excellent choice for environments where moisture or chemicals are present. This extends the lifespan of the system and reduces maintenance costs.

- 3. Modularity and Flexibility: The modular nature of the aluminum profile lean pipe system allows for easy reconfiguration and scalability. As production needs change, the system can be quickly adapted to new requirements without the need for extensive rework or new investments.

- 4. Aesthetic Appeal: Aluminum profiles offer a sleek and modern look, enhancing the visual appeal of the workplace. This can contribute to a more pleasant working environment and reflect positively on the company’s commitment to modern manufacturing practices.

- 5. Cost-Effective: While the initial investment in aluminum profiles might be higher compared to steel, the long-term benefits such as reduced maintenance, longer lifespan, and flexibility in reconfiguration make it a cost-effective solution.

Applications in Various Industries

- 1. Automotive Manufacturing: The flexibility and strength of aluminum profile lean pipe systems make them ideal for creating assembly lines, workstations, and storage solutions in the automotive industry. The ability to easily reconfigure these systems helps manufacturers adapt to changing production requirements and new vehicle models.

- 2. Electronics and Technology: In industries where precision and cleanliness are critical, aluminum profiles are an excellent choice. They can be used to construct ESD (Electrostatic Discharge) safe workstations, ensuring the protection of sensitive electronic components during assembly and testing.

- 3. Food and Beverage: The corrosion-resistant properties of aluminum make it suitable for use in the food and beverage industry, where hygiene and cleanliness are paramount. The system can be used to build storage racks, preparation stations, and transport trolleys that comply with stringent sanitary standards.

- 4. Healthcare and Pharmaceuticals: In environments that demand high standards of cleanliness and sterility, aluminum profile systems provide a hygienic and adaptable solution. They can be used to create laboratory benches, storage units, and mobile workstations that meet the rigorous demands of healthcare settings.

Implementation and Best Practices

To successfully implement an aluminum profile lean pipe system, it is essential to follow a structured approach:

- 1. Needs Assessment: Evaluate the specific requirements of your manufacturing process. Identify areas where flexibility, mobility, and durability are crucial.

- 2. Design and Planning: Work with experienced designers to create customized solutions tailored to your operational needs. Consider factors such as load-bearing capacity, ergonomics, and workflow optimization.

- 3. Assembly and Training: Ensure that your workforce is adequately trained in assembling and modifying the system. Proper training will maximize the benefits of the system’s modularity and flexibility.

- 4. Continuous Improvement: Regularly review and assess the performance of the system. Use lean manufacturing principles to identify areas for improvement and implement changes to enhance efficiency and productivity.

The Aluminum Profile Lean Pipe System represents a significant advancement in manufacturing technology. Its combination of lightweight durability, corrosion resistance, and modular flexibility makes it an invaluable tool for a wide range of industries. By adopting this system, manufacturers can achieve greater efficiency, adaptability, and cost-effectiveness, positioning themselves at the forefront of modern production practices. As industries continue to evolve, the Aluminum Profile Lean Pipe System will undoubtedly play a crucial role in shaping the future of manufacturing.