Aluminum profiles are widely used in various industries, from construction and transportation to electronics and consumer goods. Their popularity stems from aluminum’s unique combination of properties: it’s lightweight, strong, corrosion-resistant, and highly malleable. However, not all aluminum profiles are created equal, and distinguishing between high-quality and inferior products can be crucial for the success and longevity of your projects. This article outlines some simple yet effective ways to identify good aluminum profiles and avoid substandard ones.

1. Visual Inspection

The most straightforward method to assess the quality of an aluminum profile is through visual inspection. While this method may seem basic, a trained eye can detect numerous indicators of quality.

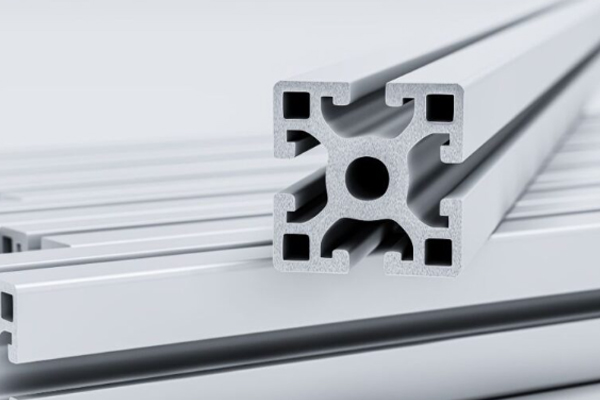

Surface Finish: High-quality aluminum profiles typically have a smooth, uniform surface finish without visible defects such as cracks, blisters, or peeling. The presence of any of these issues may suggest that the profile was not produced under optimal conditions, such as improper extrusion or inadequate cooling. For anodized profiles, the surface should be evenly coated, with a consistent color and no signs of fading or discoloration.

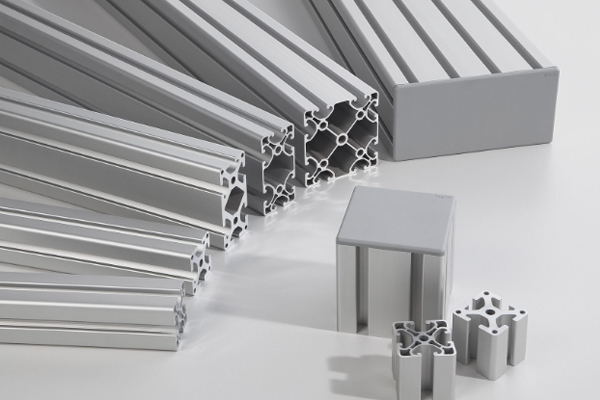

Straightness and Symmetry: Good aluminum profiles should be straight and symmetrical. Any warping, bending, or twisting could indicate that the profile was mishandled or improperly stored, or that it was manufactured using subpar materials. A simple way to check this is by laying the profile on a flat surface to see if it lies flat without gaps.

Edges and Corners: Pay attention to the edges and corners of the profile. They should be sharp and well-defined, without any signs of rounding, which can occur if the die used during the extrusion process is worn out or if the extrusion process is poorly controlled.

2. Material Composition and Alloy Type

Aluminum profiles are made from different alloys, each with specific properties that make them suitable for particular applications. Commonly used alloys include the 6000 series, which combines good strength with excellent corrosion resistance and workability.

Alloy Verification: Manufacturers should provide information about the alloy used in the profile. If this information is not readily available, it could be a red flag. In some cases, you may need to conduct a chemical composition test to verify the alloy type, particularly if the application requires specific mechanical properties or corrosion resistance.

Weight and Density: Checking the weight of the aluminum profile can also provide insights into its quality. Profiles made from high-purity aluminum will have a consistent weight and density. Profiles that feel unusually light or heavy may contain impurities or fillers, which can compromise their strength and durability.

3. Mechanical Properties

The mechanical properties of aluminum profiles, such as strength, hardness, and flexibility, are critical indicators of quality. These properties are influenced by the alloy used, the extrusion process, and subsequent treatments like heat treatment or anodizing.

Tensile Strength and Hardness: Testing the tensile strength and hardness of an aluminum profile is a reliable way to assess its quality. Higher tensile strength and hardness typically indicate better-quality aluminum, capable of withstanding greater stress and wear.

Flexibility and Ductility: Good aluminum profiles should exhibit a balance between strength and flexibility. They should not be overly brittle, which could lead to cracking or breaking under pressure, nor should they be too soft, which could result in easy deformation. Conducting a simple bend test can help assess the profile’s ductility. High-quality profiles will bend without cracking and will return to their original shape when the force is removed.

4. Dimensional Accuracy

The dimensional accuracy of an aluminum profile is another critical factor to consider, especially if the profile is being used in precision applications.

Tolerance Levels: Check whether the profile meets the specified tolerance levels for dimensions. Even slight deviations can cause significant issues in assembly or fitting, particularly in industries like aerospace or automotive, where precision is paramount.

Consistency: Inspect multiple samples of the same profile to ensure consistency. High-quality manufacturing processes should produce profiles that are identical in shape, size, and properties, regardless of when or where they were produced.

5. Supplier Reputation and Certifications

Finally, consider the reputation of the supplier and whether the aluminum profiles come with relevant certifications.

Supplier Reputation: Established manufacturers with a good reputation are more likely to provide high-quality aluminum profiles. They are likely to adhere to strict quality control measures throughout the manufacturing process.

Certifications: Certifications such as ISO 9001 for quality management systems or ISO 14001 for environmental management can serve as indicators of a supplier’s commitment to maintaining high standards. Additionally, industry-specific certifications, like those required in aerospace or automotive sectors, further guarantee that the profiles meet rigorous quality requirements.

Distinguishing between good and bad aluminum profiles is crucial for ensuring the success and longevity of your projects. By conducting a thorough visual inspection, verifying the material composition and mechanical properties, checking for dimensional accuracy, and considering the reputation and certifications of the supplier, you can make an informed decision. Investing in high-quality aluminum profiles may come with a higher upfront cost, but the long-term benefits in terms of performance, durability, and safety far outweigh the initial expense.