Description

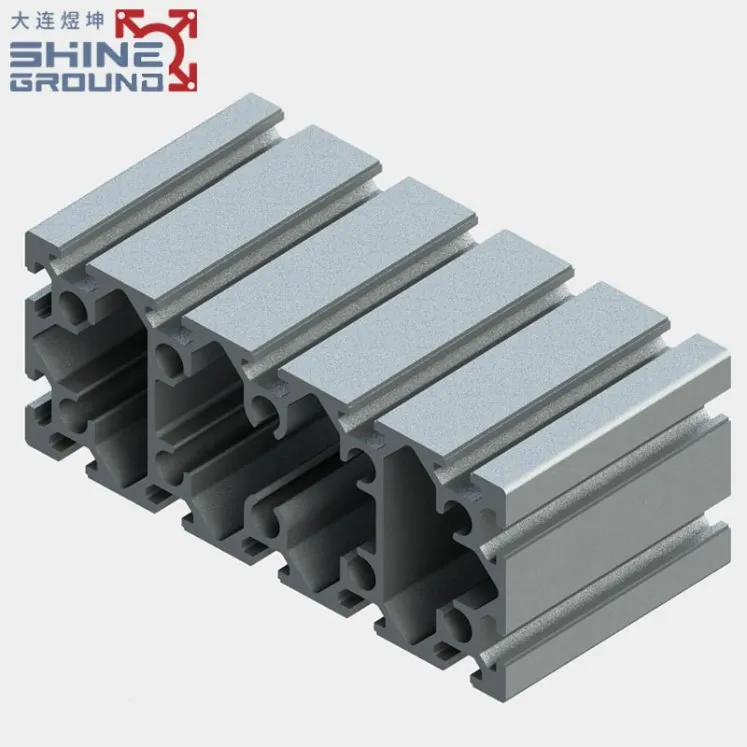

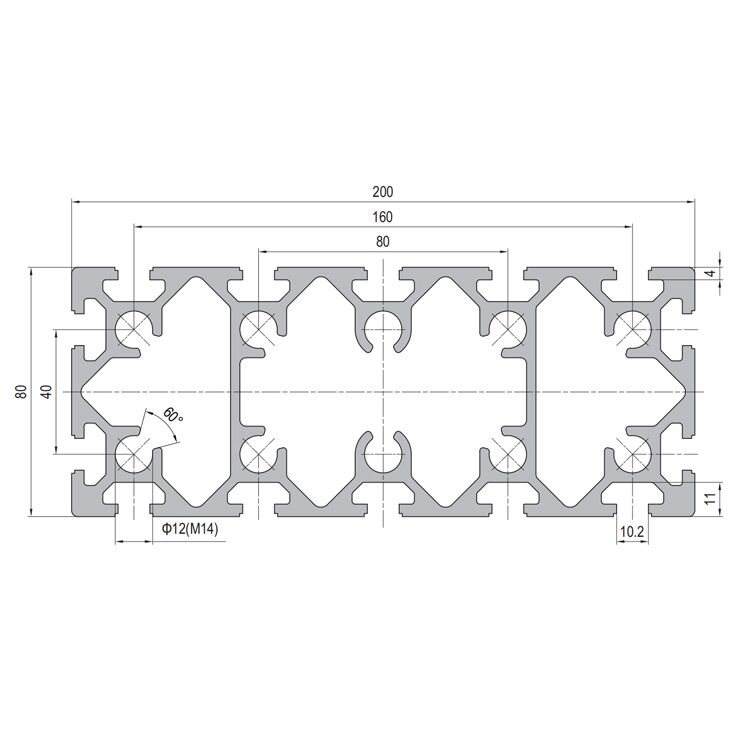

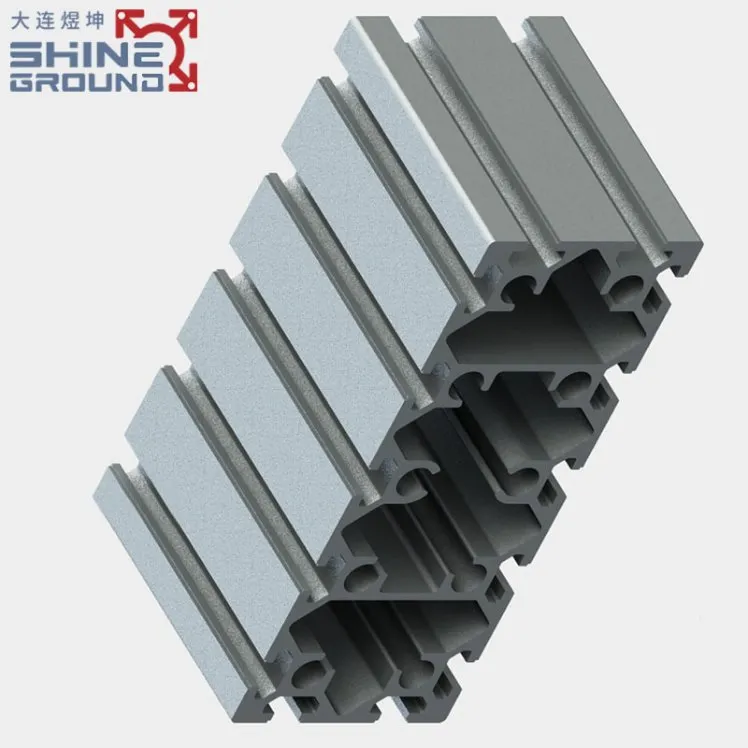

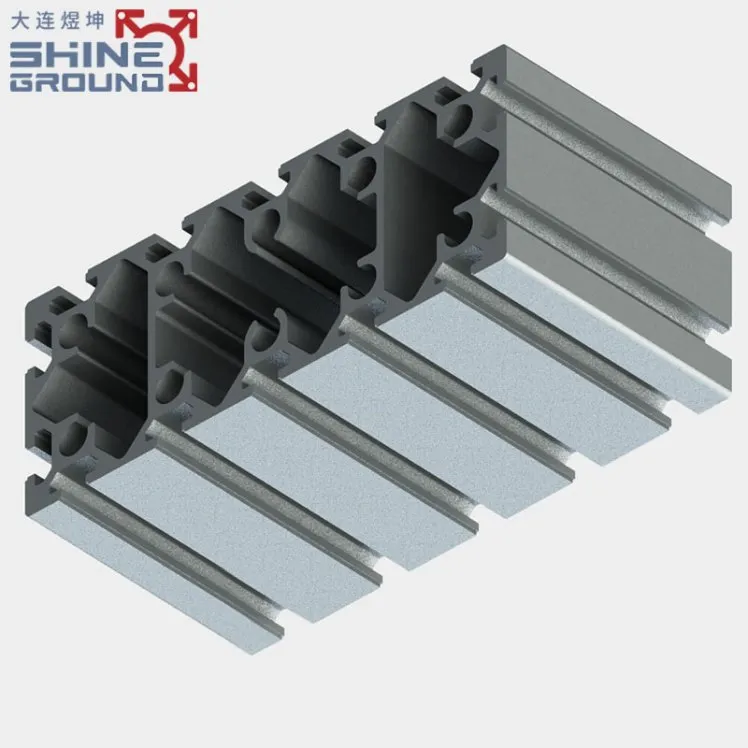

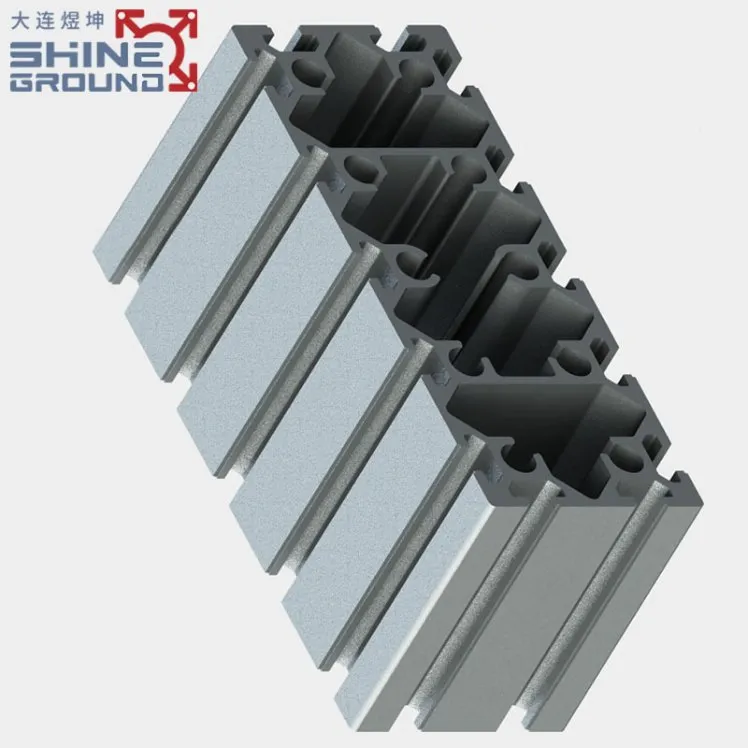

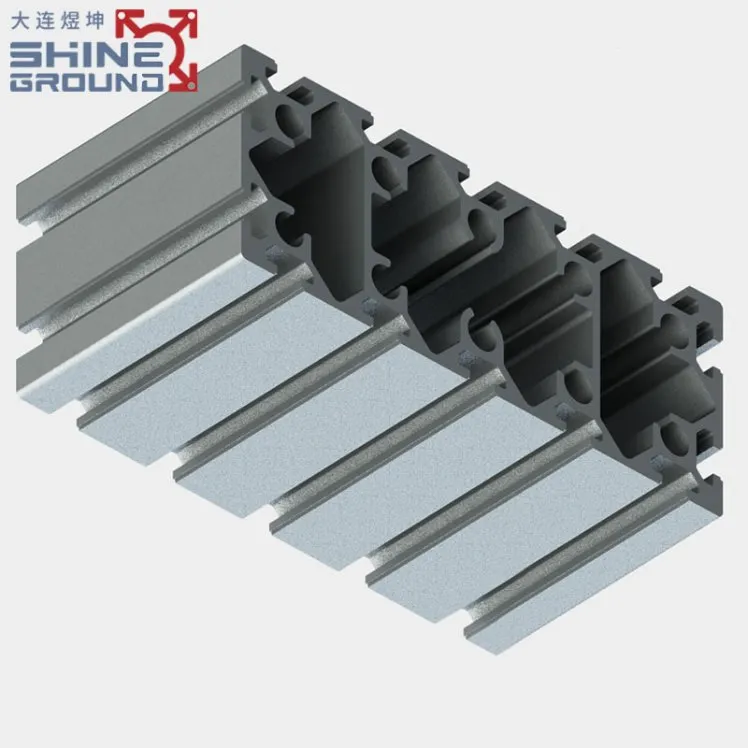

Our 80×200 mm aluminum alloy extrusion profile is a heavy-duty structural component engineered for robust performance in demanding industrial and automation environments. Fabricated from high-quality 6000-series aluminum alloy (such as 6061 or 6063), it achieves an optimal balance of strength, corrosion resistance, and machinability. The substantial cross-section, integrated with 14 strategically placed T-slots (typically 10mm), offers unparalleled modularity and mounting versatility along its entire length. This makes it an ideal, weld-free building block for constructing sturdy frames, machines, and structures that require high load-bearing capacity and long-term stability. It is commonly supplied in mill finish or with a protective anodized coating (e.g., clear silver, black) for enhanced durability and a professional appearance.

- High Strength & Durability: Designed for medium to heavy-weight applications, this profile provides exceptional structural integrity and load capacity, capable of withstanding high tension stress.

- Modular T-Slot Design: The 14 T-slots enable simple, flexible assembly and reconfiguration using standard T-nuts, bolts, and brackets, eliminating the need for welding and allowing for easy modifications.

- Superior Corrosion Resistance: The inherent properties of the aluminum alloy, often enhanced by anodizing, provide excellent resistance to corrosion, ensuring reliability in challenging industrial environments.

- Lightweight Yet Robust: Aluminum construction offers a superior strength-to-weight ratio, simplifying handling and installation while reducing the overall weight and associated structural costs of the final assembly.

- Design Flexibility: The multiple T-slots on all faces grant significant freedom for component placement and integration, facilitating custom designs for a wide range of applications from machine frames to workstations.

Reviews

There are no reviews yet.