In robotics, precision, adaptability, and efficiency are non-negotiable. T-slot aluminum profiles have emerged as a foundational material, revolutionizing how robots are designed, built, and deployed. Their modularity, cost-effectiveness, and ease of assembly make them indispensable across industrial automation, research labs, and educational settings. Here’s how T-slot profiles are shaping the future of robotics.

I. Key Applications in Robotics

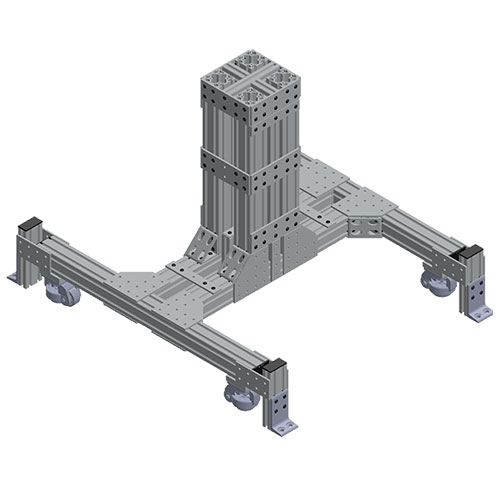

- Robotic Frames and Structural Integrity

T-slot aluminum forms the skeleton of robots—from industrial arms to mobile AGVs. Its rigidity supports motors, sensors, and actuators while minimizing weight. For example, in multi-cavity aluminum tube bending systems, T-slot platforms secure molds and maintain structural stability under stress, preventing deformation during high-precision tasks. - End-Effectors and Grippers

Custom grippers for pick-and-place operations leverage T-slots to integrate pneumatic cylinders, vacuum cups, or sensors. The slots allow rapid reconfiguration for handling diverse objects, enhancing versatility without costly redesigns. - Sensor Mounting and Protection

Robots rely on precise sensor placement for navigation and interaction. T-slots enable adjustable brackets for LiDAR, cameras, or encoders. Enclosures built from profiles also shield electronics from dust, moisture, and impacts—critical in rugged environments like agriculture or manufacturing. - Educational and Research Platforms

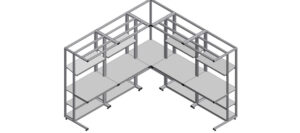

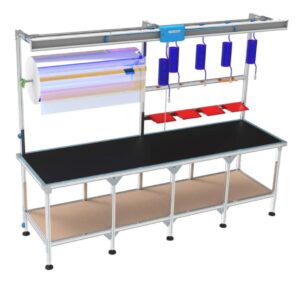

Universities like Shanghai Jiao Tong use T-slot profiles in VEX robotics kits. Students assemble modular frames for competition robots, learning mechanical design and rapid prototyping. The reusability of profiles reduces costs and accelerates experimentation. - Workstations and Conveyor Integration

In automated production lines, T-slot-built workstations and conveyors seamlessly integrate with robotic arms. The modularity supports quick reconfiguration for tasks like assembly or packaging, adapting to evolving manufacturing needs.

II. Advantages Driving Adoption

- Cost Efficiency: Significantly cheaper than steel or titanium, with reusable components minimizing waste.

- Design Flexibility: Engineers iterate rapidly—cutting, assembling, and modifying structures without welding or machining.

- Reduced Development Time: Prototypes like origami-inspired continuum robots use slot-tab locking features for swift assembly, speeding R&D cycles3.

- Ease of Maintenance: Modular design allows component replacement without disassembling entire systems, reducing downtime.

III. Challenges and Solutions

- Load-Bearing Limits: While suitable for most robots, heavy-duty applications (e.g., lifting >100 kg) may require steel reinforcement or high-strength alloys like 6063-T51.

- Thermal Expansion: Aluminum’s sensitivity to temperature shifts can cause misalignment. Solutions include expansion joints or hybrid designs with thermally stable materials.

- Aesthetics: Anodizing or powder coating improves appearance for consumer-facing robots but adds cost.

IV. Future Outlook

T-slot profiles will play a pivotal role in emerging trends:

- Semantic SLAM Integration: Modular sensor mounts enhance environmental mapping for agricultural robots navigating dynamic fields4.

- AI-Driven Automation: Platforms like VEX robots use profiles to test AI vision systems for object detection and path planning2.

- Sustainable Robotics: Reusability aligns with circular economy goals, reducing material waste.

Conclusion

T-slot aluminum profiles are more than hardware—they’re enablers of innovation. By balancing strength, flexibility, and affordability, they empower engineers to build smarter, adaptable robots ready for tomorrow’s challenges. As robotics permeates industries from manufacturing to healthcare, this unassuming material will remain the silent hero in the background.