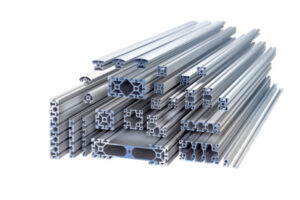

1. Introduction and Core Properties

Staircases serve as critical vertical transportation elements where material choice profoundly impacts functionality, durability, and aesthetics. Aluminum profiles have emerged as a premier solution, leveraging unique properties such as lightweight design (up to 60% lighter than steel or concrete), exceptional corrosion resistance (due to a self-healing oxide layer), and high strength-to-weight ratio (achieved through engineered alloys). These profiles also offer aesthetic flexibility via extrusion versatility and surface treatments like anodizing or powder coating, alongside sustainability from near-infinite recyclability (using ~5% of primary production energy).

2. Residential Applications: Elegance and Resilience

In homes, aluminum stair systems excel both indoors and outdoors. Indoors, they integrate seamlessly with glass or wood for modern, open designs that enhance light flow and spatial aesthetics. Outdoors, their corrosion resistance ensures longevity in harsh environments like coastal areas or poolside settings. Aluminum’s adaptability supports custom designs, from minimalist floating stairs to space-saving spirals, meeting diverse architectural styles while minimizing maintenance.

3. Commercial and Industrial Versatility

Commercial spaces (malls, offices, hotels) benefit from aluminum’s capacity to handle heavy foot traffic while maintaining visual appeal. Rapid installation of prefabricated components reduces construction downtime, and custom designs project professionalism or luxury. In industrial settings (factories, warehouses), aluminum’s durability withstands chemicals, moisture, and mechanical stress. Modular designs enable features like anti-slip treads, and sustainability aligns with eco-friendly certifications.

4. Installation and Maintenance Efficiency

- Installation: The process begins with CAD-based design, factoring in loads, space, and usage. Profiles are precision-extruded, cut, and surface-treated off-site. On-site assembly leverages lightweight components and bolted connections, slashing construction time.

- Maintenance: Requires only periodic cleaning with mild detergents, inspections for structural integrity, and lubrication of moving parts. Unlike wood or steel, aluminum avoids rust, rot, or extensive refurbishment.

5. Comparative Advantages and Solutions to Challenges

Aluminum outperforms alternatives:

- vs Steel: Lighter, corrosion-resistant (no rust), and lower lifetime maintenance.

- vs Concrete: Faster installation, design flexibility, and recyclability.

- vs Wood: Immune to insects/moisture, fire-resistant, and maintenance-free.

Challenges Addressed: Higher initial costs are offset by longevity and recyclability. Thermal conductivity is mitigated via thermal breaks, while dissimilar-metal corrosion is prevented with insulating gaskets.

6. Future Trends and Conclusion

Advancements in 3D printing and precision extrusion will enable more complex, cost-effective designs. Sustainability imperatives drive demand for recycled-content profiles and closed-loop recycling. Smart technologies, such as embedded sensors for load monitoring and adaptive lighting, will enhance safety and user experience.

Conclusion: Aluminum staircase systems offer unmatched versatility, durability, and eco-efficiency across residential, commercial, and industrial domains. As manufacturing innovations and smart integrations evolve, aluminum will continue redefining vertical mobility solutions.