1. Material Characteristics

6063 aluminum alloy (Al-Mg-Si system) demonstrates exceptional properties for industrial frameworks:

- Lightweight: Density of 2.69g/cm³ reduces equipment inertia

- Corrosion Resistance: Natural oxide layer prevents degradation in industrial environments

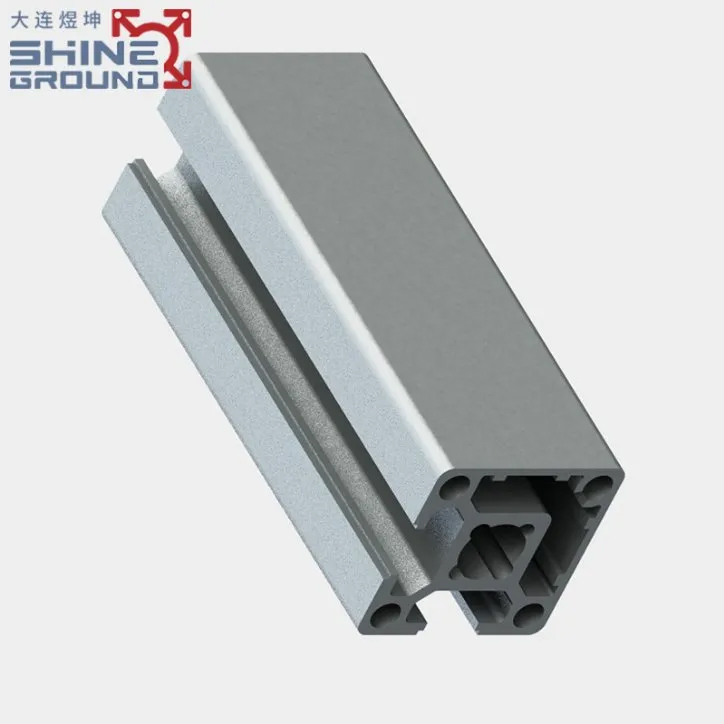

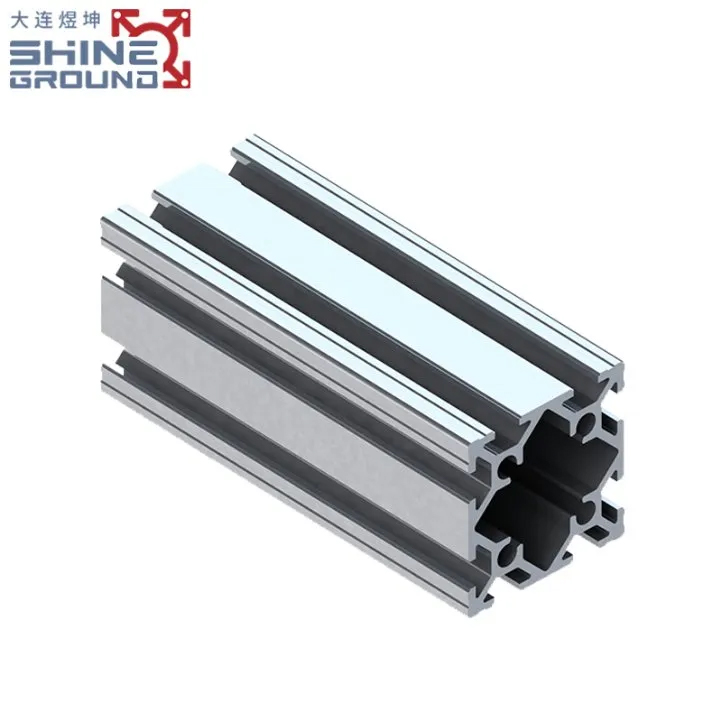

- Formability: Excellent extrusion capability for complex cross-sections

- Thermal Conductivity: 209W/(m·K) aids heat dissipation in electronic components

2. Structural Applications

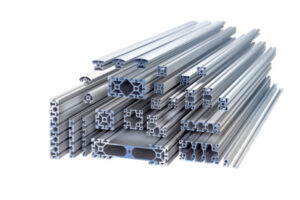

- Modular Frameworks:Standard profiles (20×20mm to 120×120mm) form building blocks for:

- Assembly lines (80% of Chinese automation lines use 6063)

- Robotic workstations with T-slot design for adjustable mounting

- Conveyor systems (load capacity up to 500kg/m)

- Specialized Components

- Protective Enclosures: 3-5mm thick panels with IP54-rated joints

- Precision Slides: Anodized rails (Ra≤0.8μm) for linear motion systems

- Vibration Dampers: Hollow profiles with internal ribbing reduce resonance

3. Manufacturing Advantages

- Processing Techniques

- T5 Tempering: Air-cooled after extrusion (typical hardness: 75HB)

- Surface Treatments:

- Anodizing (10-25μm) for wear resistance

- Powder coating (60-120μm) for chemical protection

- Joining Methods:

- Corner brackets (45°±0.5° precision)

- T-slot nuts (M6/M8 standard)

- T5 Tempering: Air-cooled after extrusion (typical hardness: 75HB)

- Cost Efficiency

- 30-50% lower tooling costs vs steel frameworks

- 60% faster assembly than welded structures

- 100% recyclability meets circular economy standards

4. Industry-Specific Implementations

- Electronics Manufacturing

- SMT equipment frames with ESD protection

- Cleanroom-compatible profiles (ISO Class 5)

- Automotive Assembly

- Battery pack enclosures (600V insulation)

- Welding jigs with 0.1mm/m dimensional stability

- Packaging Systems

- Hygienic designs with radius corners (r≥3mm)

- Washdown-resistant coatings for food applications

5. Performance Comparison

| Parameter | 6063-T5 | Steel Equivalent | Advantage |

| Weight (kg/m³) | 2,690 | 7,850 | 66%lighter |

| Thermal Expansion | 23.4μm/m·K | 12μm/m·K | Better thermal matching |

| Fatigue Strength | 90MPa | 250MPa | Adequate for dynamic loads |

| Lead Time | 2 weeks | 6 weeks | Faster prototyping |

6. Future Trends

- Hybrid Structures: Combining 6063 with carbon fiber reinforcements

- Smart Integration: Embedding sensors in extruded channels

- Green Manufacturing: Low-carbon footprint production (8kg CO2/kg vs 2.3kg for steel)

Typical Application Case of 6063 Aluminum Profiles in Automation Production Line Frames: Technical Innovation and Engineering Practice

7. Case Background

A smart assembly line for new energy battery modules (deployed in 2025)

This production line needs to achieve precise assembly of 12 battery packs per minute, while requiring the frame structure to have electromagnetic interference (EMI) resistance, dust-tight sealing, and high-frequency vibration resistance. The core frame system is constructed using 6063-T5/T6 aluminum profiles, with a total aluminum consumption of 28 tons.

- Structural Design

- Dual-Cavity Main Frame

- Mechanical Optimization: Adopts an internal-external dual-cavity nested design, with an inner cavity cross-section of 40×80mm (wall thickness 3.5mm) and an outer cavity of 60×100mm (wall thickness 4mm). Connected by 30° staggered partitions, the flexural rigidity is increased by 217% compared to traditional single-cavity structures.

- Vibration Suppression: Integrates honeycomb damping structures with polyurethane shock pads, controlling vibration amplitude within ±0.03mm during operation to meet the precision requirements of laser welding stations.

- Modular Functional Units

- Standard Units: 80×80mm profiles form the conveyor base, with a load capacity of 800kg per meter. The T-slot design allows quick adjustment of roller spacing.

- Protection System: 40×40mm profiles with sealing strips build an IP67-rated dust-proof cover, integrating LED lighting and pneumatic pipeline channels.

- Electrical Integration: Copper busbar wiring grooves embedded inside the profiles enable separate routing of low-voltage and high-voltage cables, achieving an electromagnetic shielding effectiveness of 40dB@1GHz.

- Dual-Cavity Main Frame

- Performance Optimization

- Enhanced Dynamic Stability

- Finite element analysis (FEA) optimizes node design. Critical connection points use reinforced corner brackets (tensile strength ≥220MPa), shifting the frame’s natural frequency outside the equipment’s vibration frequency band (15–60Hz).

- After assembly, sweep frequency testing shows the resonance peak attenuation rate increases from 45% (traditional structure) to 82%.

- Cleanroom Adaptation

- Surface treated with hard anodizing (25μm film thickness, hardness ≥400HV) and cleanroom-specific powder coating (friction coefficient ≤0.15), meeting ISO 14644-1 Class 5 standards.

- Rounded corners (r=5mm) and seamless splicing eliminate dead corners for particle accumulation.

- Enhanced Dynamic Stability

- Implementation Results

| Indicator | Pre-Refurbishment (Steel Structure) | 6063 Aluminum Profile Solution | Improvement |

| Production Line Self-Weight | 52 tons | 28 tons | 46%↓ |

| Installation Cycle | 35 days | 18 days | 49%↓ |

| Positioning Accuracy | ±0.15mm | ±0.05mm | 67%↑ |

| Energy Consumption Index | 1.0 | 0.68 | 32%↓ |

| Annual Maintenance Cost | ¥245,000 | ¥98,000 | 60%↓ |

Data source: Project acceptance report (2025 Q2)

8. Extended Applications

Medical Equipment Frames: Antibacterial-coated 6063 profiles used in CT machine mobile brackets, complying with DIN EN 61340-5-1 electrostatic protection standards.

Semiconductor Wafer Handling Systems: Ultra-flat profile rails (flatness ≤0.02mm/m) paired with ceramic rollers achieve nanometer-level positioning.

This case demonstrates that through structural innovation and process upgrades, 6063 aluminum profiles can replace traditional materials in high-precision industrial scenarios. Their “customizable performance + rapid deployment” characteristics are driving the iteration of smart manufacturing equipment.