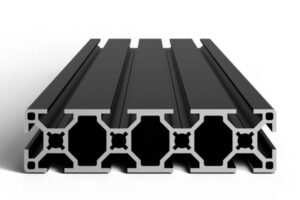

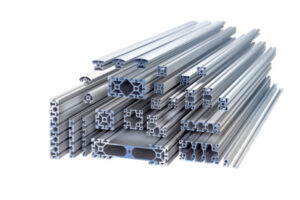

The Application of T-Slot Aluminum Profiles in the Automation Field

1. Introduction In the fast – evolving automation landscape, material selection is key to determining the efficiency, durability, and functionality of automated systems. T – slot aluminum profiles have become a preferred choice, with numerous advantages making them essential in various automation applications. This article explores their properties, applications, and