The production of aluminium profiles is a systematic and delicate process, involving a number of key links, which are described in detail below:

1. Casting

- Batching: According to the alloy composition requirements of the target aluminium profiles, the required pure aluminium, alloying elements (such as magnesium, silicon, copper, etc.) and intermediate alloys are accurately calculated and weighed. For example, when producing 6063 alloy aluminium profiles, the content of magnesium and silicon needs to be strictly controlled to ensure the strength, corrosion resistance and other properties of the profiles.

- Melting: The matched raw materials are added into the melting furnace and heated to above the melting point of aluminium (generally the melting point of pure aluminium is about 660℃), so that it is completely melted. During the melting process, the aluminium liquid should be stirred continuously to ensure uniform composition, and measures should be taken to remove gas and slag to remove hydrogen and inclusions in the aluminium liquid and to improve the purity of the aluminium liquid.

- Casting: The refined aluminium liquid is injected into the crystallizer through the casting machine, and cooled and solidified to form aluminium ingots or bars. Commonly used casting methods include semi-continuous casting, which can produce aluminium rods with longer length and stable quality, and provide qualified billets for subsequent extrusion moulding.

2. Extrusion

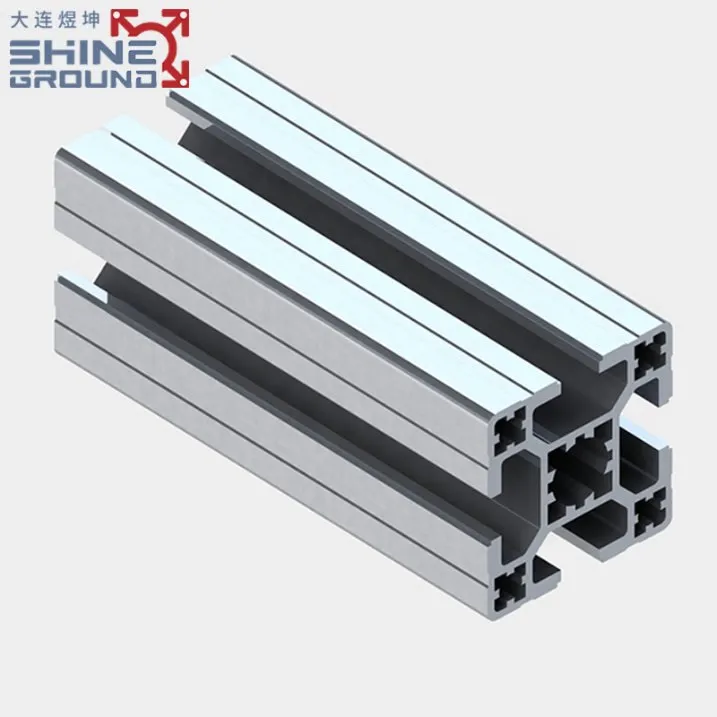

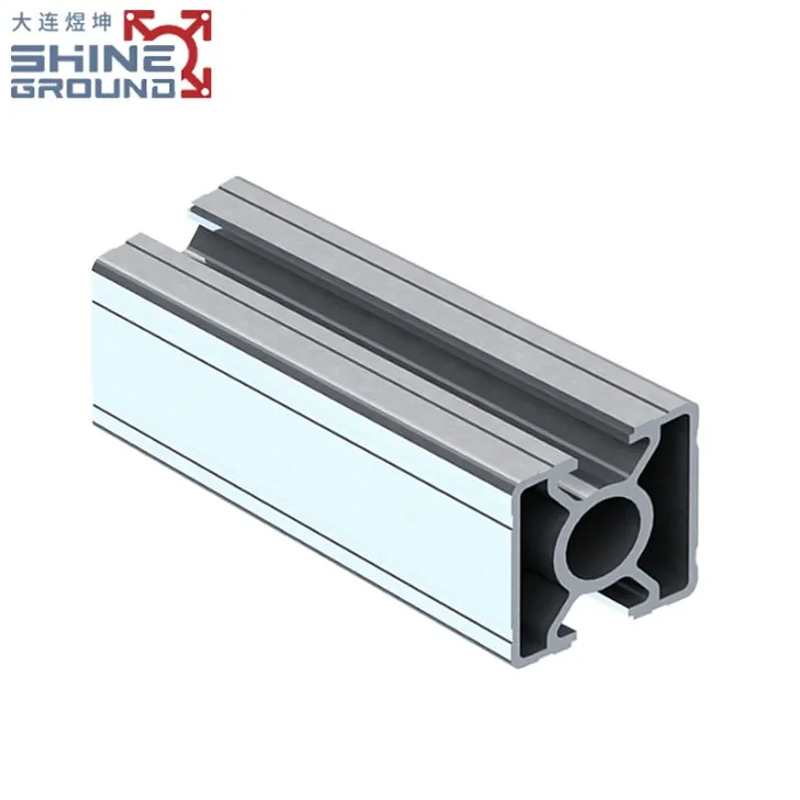

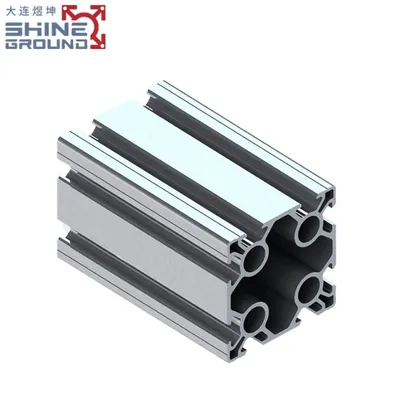

- Die design and manufacture: according to the requirements of the cross-section shape and size of aluminium profiles, design and manufacture special extrusion dies. The design accuracy and manufacturing quality of the dies directly affect the forming effect and quality of aluminium profiles. For example, for complex profiles, the design of the die needs to take into account the uniformity of the metal flow to avoid defects such as twisting and waving.

- Aluminium bar heating: The cast aluminium bar is put into a heating furnace and heated to a suitable extrusion temperature (generally depending on the type of alloy, e.g. the extrusion temperature of 6063 alloy is usually between 480 – 520°C). The purpose of heating is to make the aluminium bar have good plasticity, so as to facilitate plastic deformation in the extrusion process.

- Extrusion: The heated aluminium bar is put into the extrusion barrel of the extruder, and pressure is exerted through the extrusion shaft, so that the aluminium bar undergoes plastic deformation under the action of the die, and is extruded out of the die holes of the die to form aluminium profiles of the required cross-section shape. During the extrusion process, parameters such as extrusion speed, extrusion temperature and extrusion ratio need to be strictly controlled to ensure the quality and performance of the profile.

- Cooling and Straightening: The temperature of the extruded aluminium profile is high, so it needs to be cooled down to make it cool down quickly and fix its shape. Commonly used cooling methods include air cooling and water cooling. After cooling, the aluminium profile may be bent, twisted and other deformations, which need to be straightened by the straightening machine, so as to make it reach the specified straightness requirements.

3. Surface treatment

- Pre-treatment: Surface pre-treatment is carried out on straightened aluminium profiles to remove surface impurities such as oil, oxide skin, etc., and to improve the surface activity and adhesion of the coating. Pretreatment methods include alkali washing, acid washing, neutralisation, water washing and other steps.

- Anodic oxidation: The pre-treated aluminium profile is used as an anode, put into an electrolytic tank, and pass direct current in acidic electrolyte (e.g. sulphuric acid solution), so that the surface of the aluminium profile undergoes an anodic oxidation reaction to generate a dense layer of aluminium oxide film. The thickness and performance of the oxide film can be controlled by adjusting parameters such as electrolyte concentration, temperature, current density and oxidation time. Anodic oxidation can improve the corrosion resistance, wear resistance and decorative properties of aluminium profiles.

- Colouring: According to the needs, the aluminium profiles after anodic oxidation are coloured to make them have different colours. Colouring methods include electrolytic colouring, chemical colouring and organic dye colouring. Among them, electrolytic coloring is in the electrolyte containing metal salts, through the second electrolysis to make metal ions deposited in the micropores of the oxide film to form various colours; chemical coloring is to make use of chemical reagents to have chemical reaction with the oxide film to make the oxide film coloring; organic dyes coloring is to adsorb organic dyes in the micropores of the oxide film to achieve the purpose of coloring.

- Sealing: After colouring the aluminium profiles need to be sealed to close the pores of the oxide film, to prevent external impurities and corrosive media from entering, and to improve the corrosion resistance and pollution resistance of the oxide film. Commonly used sealing methods include hot water sealing, steam sealing and cold sealing.

4. Subsequent processing and inspection

- Sawing: According to the length required by the customer, use the sawing machine to saw the aluminium profile after surface treatment into the specified size. During the sawing process, it is necessary to ensure that the kerf is smooth and burr-free, and the dimensional accuracy meets the requirements.

- Deep processing: according to the needs, the aluminium profile is further deep processing, such as drilling, tapping, milling, stamping, etc., to meet different assembly and use requirements.

- Inspection: The processed aluminium profiles are subjected to comprehensive quality inspection, including the inspection of appearance quality (such as whether there are scratches, bubbles, colour difference on the surface, etc.), dimensional accuracy (such as length, width, thickness, angle, etc.), mechanical properties (such as tensile strength, yield strength, elongation, etc.) and corrosion resistance. Only aluminium profiles with qualified inspection can enter the finished product warehouse and be sold at the factory.