Aluminum production is a complex and energy-intensive process, mainly divided into bauxite mining and beneficiation, alumina refining, electrolytic aluminum smelting, aluminum refining and casting, as well as aluminum processing of five key steps, the following is a detailed introduction:

1. Bauxite mining and beneficiation

- Raw material source: Bauxite is the main ore of aluminum, and its main component is a mixture of alumina and hydrated alumina. Global bauxite reserves are abundant, mainly concentrated in Guinea, Australia, Brazil, China and other places.

- Mining method: Bauxite mining is divided into open pit mining and underground mining, the specific choice depends on the burial depth of the ore body and geological conditions.

- Beneficiation treatment: After mining, bauxite ore needs to be crushed, washed and other beneficiation treatment to improve the grade of the ore (alumina content should be more than 40%) and remove impurities.

2. Alumina refining (Bayer method mainly)

- Dissolution: Bauxite ore reacts with sodium hydroxide solution at high temperature and pressure to produce a sodium aluminate solution. During this process, alumina is dissolved from the ore, while impurities form an insoluble silicate residue.

- Settling and Separation: The sodium aluminate solution is diluted and settled to separate the insoluble red mud. Red mud needs to be treated in an environmentally friendly way to prevent pollution to the environment.

- Decomposition of crystal species: Aluminum hydroxide crystal species are added to the sodium aluminate solution, and the precipitation of aluminum oxide in the form of aluminum hydroxide is induced by cooling and stirring.

- Calcination: The precipitated aluminum hydroxide is calcined at high temperature and dehydrated to produce metallurgical grade alumina, the purity of which can be more than 98%.

3. Aluminum electrolysis smelting (Hall-Eroute method)

- Electrolyzer structure: Modern aluminum electrolysis uses a prebaked anode electrolyzer with cryolite as the melting agent, in which alumina is dissolved to form the electrolyte.

- Electrolytic reaction:

- Cathodic reaction: aluminum ions (Al³⁺) get electrons at the cathode and are reduced to liquid aluminum (Al), which is deposited at the bottom of the electrolyzer.

- Anodic reaction: Oxygen ions (O²-) lose electrons at the anode and react with the carbon anode to form carbon dioxide (CO₂).

- Aluminum discharge and casting: Liquid aluminum is periodically withdrawn from the electrolyzer, purified and cast into ingots (generally 99.7% pure primary aluminum).

4. Aluminum refining and casting

- Refining treatment: In order to remove hydrogen, sodium, calcium and other impurities in the liquid aluminum, usually chlorine and inert gases are introduced into the liquid aluminum, so as to volatilize or precipitate the impurities through physical and chemical effects.

- Filtration treatment: using ceramic foam filters and other equipment to further remove oxide inclusions in the liquid aluminum and improve the purity of the liquid aluminum.

- Composition Adjustment: According to product requirements, alloying elements (e.g. copper, magnesium, silicon, zinc, etc.) are added to the liquid aluminum to produce different grades of aluminum alloys.

- Casting: The refined aluminum liquid or aluminum alloy liquid is injected into the mold and cooled and solidified to form primary products such as aluminum ingots, aluminum rods and aluminum slabs.

5. Aluminum processing

- Rolling: Aluminum ingots or slabs are processed into aluminum plates and strips of different thicknesses and widths through hot rolling and cold rolling processes.

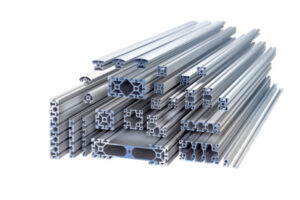

- Extrusion: Put the heated aluminum alloy billet into the extruder and extrude it into aluminum profiles of various cross-sectional shapes (e.g., aluminum tubes, aluminum rods, aluminum profiles, etc.) by means of dies.

- Forging: using forging equipment to exert pressure on aluminum alloy billets to produce plastic deformation and make high-strength aluminum forgings.

- Stretching and Further Processing: Through stretching, stamping, bending and other processes, aluminum is processed into various parts and products, such as aluminum foil, aluminum cans, aluminum doors and windows.

- Surface treatment: In order to improve the corrosion resistance, abrasion resistance and aesthetics of aluminum, it is often subjected to anodic oxidation, electrophoretic coating, powder coating and other processes.