When sourcing aluminium for industrial or commercial use, one of the most frequently asked questions is: How many grades of aluminium are there, and what makes them different? Aluminium is an extremely versatile metal, but not all aluminium is created equal. Understanding the different grades and alloy types is key to selecting the right material for your project.

What Are Aluminium Grades?

Aluminium grades refer to the chemical composition and mechanical properties of a specific aluminium alloy. Pure aluminium (known as 1000 series) is soft and corrosion-resistant, while aluminium alloys are blended with elements like magnesium, silicon, copper, zinc, or manganese to enhance strength, weldability, or machinability.

Globally, aluminium grades are often classified using the four-digit alloy numbering system developed by the Aluminum Association (AA), such as 6061, 6063, 2024, etc.

The Major Aluminium Series: 1000 to 8000

There are eight main aluminium series, each representing a different group of alloys:

- 1000 Series (Pure Aluminium, ≥99%)

High corrosion resistance, excellent thermal and electrical conductivity. Used in electrical conductors, food packaging, and chemical equipment. - 2000 Series (Al-Copper Alloys)

High strength but lower corrosion resistance. Common in aerospace applications. Example: 2024. - 3000 Series (Al-Manganese Alloys)

Good corrosion resistance, moderate strength. Often used in roofing sheets, cookware, and air conditioners. Example: 3003. - 4000 Series (Al-Silicon Alloys)

Good wear resistance and low thermal expansion. Used in engine components and automotive applications. - 5000 Series (Al-Magnesium Alloys)

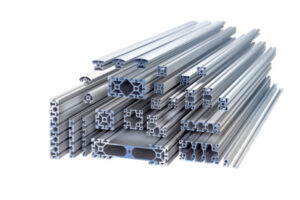

Excellent corrosion resistance and weldability. Widely used in marine, transport, and architecture. Example: 5052, 5083. - 6000 Series (Al-Mg-Si Alloys)

Balanced strength, corrosion resistance, and good extrudability. Ideal for aluminium profiles used in construction and industrial frames. Example: 6061, 6063. - 7000 Series (Al-Zinc Alloys)

Ultra-high strength, often used in aerospace and sporting equipment. Example: 7075. - 8000 Series (Miscellaneous Alloys)

Includes lithium and iron alloys. Common in battery foils, packaging, and specialty applications.

Which Aluminium Grades Are Most Common?

For general industrial and construction use, the most popular grades are:

- 6061 Aluminium: Strong, machinable, weldable. Used in frameworks, machine parts, and automotive components.

- 6063 Aluminium: Superior surface finish, ideal for architectural and decorative aluminium profiles.

- 5052 Aluminium: Known for its excellent corrosion resistance in marine applications.

- 3003 Aluminium: Lightweight and inexpensive; often used in cooking utensils and roofing.

Choosing the Right Aluminium Grade

Choosing the correct grade depends on your application:

- Need corrosion resistance? → Choose 1000 or 5000 series.

- Need structural strength? → Go with 2000, 6000, or 7000 series.

- Need good surface finish for anodizing? → 6063 is a great choice.

- Need to weld or form sheets? → 3003 and 5052 work well.

Also, remember that each alloy can come in different tempers (like T5, T6, H32), which further define its strength and processing condition.

So, how many grades of aluminium are there? Technically, hundreds—each with its own combination of elements, strengths, and properties. But they can be grouped into eight main series, each suited to different industries and applications. Whether you are sourcing aluminium for marine, construction, automotive, or electronic use, understanding the alloy system is essential.

At AluminumCompo, we offer a wide selection of aluminium profiles and extrusion solutions in grades like 6063-T5, 6061-T6, and 5083, tailored to your project’s needs. Reach out to us to find the ideal aluminium alloy for your application.