1. Introduction

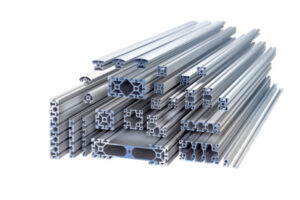

3D printing technology has evolved from prototyping to full-scale manufacturing, demanding enhanced equipment performance, precision, and scalability T-slot aluminum extrusions, with their unique combination of strength, modularity, and corrosion resistance, have emerged as a cornerstone material for constructing 3D printer frameworks and auxiliary systems. This article explores their critical role in advancing 3D printing technology.

2. Advantages of T-Slot Aluminum Extrusions

2.1 High Strength-to-Weight Ratio

Aluminum alloys like 6061 and 7075 offer tensile strengths exceeding 260 MPa while maintaining low density (~2.7 g/cm³), reducing structural weight without compromising rigidity. This is vital for high-speed 3D printers requiring minimal inertia in motion systems.

2.2 Modular Assembly

The T-slot design enables rapid assembly using bolts, nuts, and brackets, eliminating welding and allowing customizable configurations. Modularity supports easy upgrades, such as expanding print volumes or integrating new components like multi-axis systems.

2.3 Corrosion Resistance

Natural oxide layers and anodized finishes protect against moisture, acids, and printing byproducts (e.g., resin fumes), ensuring longevity in diverse environments.

2.4 Machinability and Customization

Aluminum extrusions are easily cut, drilled, or milled to accommodate sensors, cable management, or specialized mounts. Surface treatments like powder coating enhance wear resistance for industrial applications.

3. Core Applications in 3D Printing

3.1 Printer Frames

- Industrial-Scale Printers: Large-format FDM/SLS printers use 8080 or 100100 series extrusions for stability, supporting print beds up to 1,000 mm³ while maintaining ±0.05 mm layer accuracy.

- Desktop Systems: 4040 series extrusions enable compact, lightweight frames for multi-material or bioprinters, balancing portability and precision.

3.2 Motion Systems

- Linear Rail Mounting: T-slots secure guide rails for X/Y/Z-axis movements, ensuring parallelism and reducing vibration during high-speed printing (e.g., 150 mm/s).

- Multi-Axis Integration: Modular designs facilitate complex motion systems for 5-axis printers or hybrid machines combining 3D printing with CNC milling.

3.3 Work Platforms

- Adjustable Bed Supports: T-slot assemblies with leveling bolts and springs enable automatic bed leveling, critical for adhesion in FDM printing.

- Heated Bed Integration: Aluminum’s thermal conductivity aids heat dissipation, preventing warping in high-temperature environments (e.g., ABS printing).

3.4 Auxiliary Structures

- Filament Feeders: Custom brackets guide filaments smoothly to print heads, reducing jams in flexible or composite materials6.

- Safety Enclosures: Modular frames with transparent panels protect users from moving parts and stabilize print environments against dust or airflow.

4. Case Studies

4.1 Industrial FDM Printer (1,000 mm³ Build Volume)

- Framework: 8080-series extrusions with high-strength corner brackets achieved 150 mm/s print speeds and ±0.05 mm accuracy for aerospace prototypes.

- Motion System: Linear rails mounted on T-slots reduced inertia, enabling rapid directional changes without compromising precision.

4.2 Desktop Multi-Material Printer

- Modular Design: 4040-series extrusions supported three independent nozzles, enabling simultaneous printing with PLA, TPU, and PVA.

- Self-Leveling Bed: Spring-loaded T-slot adjustments automated bed calibration, improving first-layer adhesion.

5. Future Trends

5.1 Integration with Advanced Printing Technologies

- Multi-Material Systems: T-slot frameworks will support hybrid printers combining extrusion, resin, and metal deposition16.

- Bioprinting: Corrosion-resistant extrusions enable sterile environments for tissue engineering, leveraging modularity for scalable bioreactor integration.

5.2 Smart Manufacturing

- Sensor Integration: T-slots embed strain gauges or thermal sensors for real-time monitoring of frame stress and print conditions.

- Automation: Robotic arms and conveyor systems mounted on aluminum frames enable lights-out manufacturing.

5.3 Sustainability

- Recyclability: Aluminum’s closed-loop recycling aligns with eco-friendly manufacturing, reducing waste in large-scale production.

- Energy Efficiency: Lightweight structures lower energy consumption in high-speed printers, supporting green manufacturing initiatives.

6. Conclusion

T-slot aluminum extrusions are pivotal in advancing 3D printing, offering unmatched versatility, durability, and adaptability. As the industry evolves toward multi-material capabilities, automation, and sustainability, these extrusions will remain central to next-generation printer design, bridging innovation and practicality.