In the rapidly evolving field of industrial automation, material selection is crucial for system efficiency, reliability, and cost-effectiveness. T-slot aluminum has become a preferred choice due to its numerous benefits, making it suitable for a wide range of applications. Its unique properties, including strength, versatility, and ease of assembly, have established it as a key component in modern industrial automation setups.

Understanding T-Slot Aluminum

- Definition and Structure

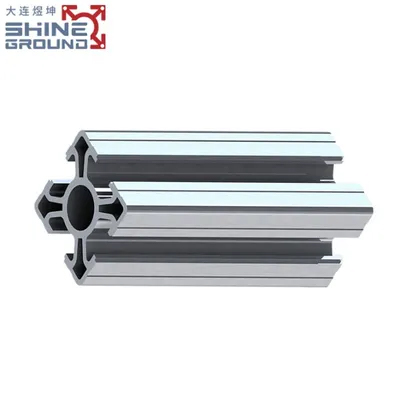

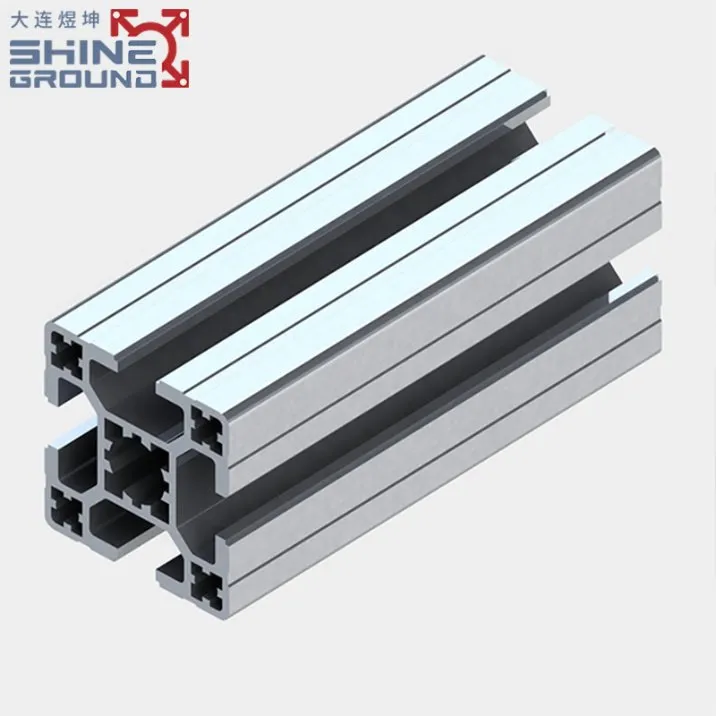

T-slot aluminum consists of extruded aluminum profiles with T-shaped grooves along their length. These grooves allow for the insertion of fastening components like T-nuts and bolts, enabling easy connection of different parts. The profiles are made from aluminum alloys, designed to enhance properties such as strength, corrosion resistance, and machinability. - Types of T-Slot Aluminum Profiles

There is a diverse range of T-slot aluminum profiles available, varying in size, wall thickness, and finish. Common metric sizes include 4040 and 4545 series for heavy-duty applications, while smaller 2020 series are suitable for lighter loads. Thicker-walled profiles offer greater strength, while thinner ones are more lightweight and cost-effective. Anodized and powder-coated finishes are popular for their corrosion resistance and durability.

Applications of T-Slot Aluminum in Industrial Automation

- Machine Frames and Structures

T-slot aluminum is widely used in constructing machine frames, providing support and stability for automated machinery. Its high strength-to-weight ratio allows it to withstand mechanical stresses while remaining lightweight, reducing energy consumption. For example, robotic arms in manufacturing plants are often mounted on T-slot aluminum frames, which can be customized to incorporate various components and ensure precise movement. - Conveyor Systems

In conveyor systems, T-slot aluminum is used for frames and supports. Its lightweight nature reduces energy consumption, and corrosion resistance ensures longevity. In food and beverage plants, T-slot aluminum conveyors are preferred for their hygiene and ease of cleaning. The modular design enables quick disassembly for maintenance. - Workstations and Ergonomic Setups

T-slot aluminum is ideal for creating workstations. It allows for customization, such as adjustable height workbenches and integration of accessories. Mobile workstations can also be created, facilitating movement on the factory floor. This helps in maximizing productivity and reducing operator fatigue.

- Safety Guarding and Fencing

Safety is paramount in industrial automation, and T-slot aluminum is used for safety guarding and fencing. It can create barriers around machinery, with panels attached to provide visibility while ensuring safety. Interlocking mechanisms can be added to prevent machine operation when guards are open. - Automated Storage and Retrieval Systems

T-slot aluminum is used in automated storage and retrieval systems (AS/RS). It enables customization of storage racks and provides strength for shuttle cars and stacker cranes. In e-commerce fulfillment centers, AS/RS systems based on T-slot aluminum can be easily reconfigured to meet changing storage needs.

Advantages of T-Slot Aluminum in Industrial Automation

- Strength and Durability

Despite being lightweight, T-slot aluminum offers excellent strength. Aluminum alloys provide high tensile and compressive strength, capable of supporting heavy loads. Its natural corrosion resistance, enhanced by finishes, ensures a long service life, reducing maintenance and replacement costs. - Versatility and Modularity

The T-slot design offers infinite connection possibilities. A wide range of components can be easily attached, enabling highly customized structures. This modularity allows for quick reconfiguration of production lines and easy upgrades as business needs change. - Ease of Assembly and Disassembly

T-slot aluminum structures are easy to assemble and disassemble using simple hand tools. This reduces installation time and labor costs, and minimizes downtime during maintenance or system reconfiguration.

- Cost-Effectiveness

Although the initial cost of T-slot aluminum may be higher than some materials, its long-term benefits make it cost-effective. Reduced maintenance, energy savings, and ease of assembly contribute to overall cost savings. - Lightweight and Energy Efficiency

The lightweight nature of T-slot aluminum reduces energy consumption in machinery with moving parts. Faster and more precise movement improves system efficiency, leading to higher production output.

T-slot aluminum has become a key material in industrial automation due to its wide range of applications and numerous advantages. As the industry continues to evolve, its role is expected to expand, enabling the creation of reliable, efficient, and cost-effective automation solutions across various industries.