Introduction

Aluminium profiles are fundamental components in modern manufacturing and construction, valued for their versatility, strength-to-weight ratio, and corrosion resistance. Mass-produced from alloys like 6061 and 6063, these extruded shapes fall into two primary categories: basic geometric shapes and modular T-slot systems.

Understanding these standard profiles helps businesses select the right materials for their projects efficiently. From simple angles and channels to complex T-slot systems, aluminium profiles offer endless possibilities for design and construction.

Common Standard Shapes

Basic geometric aluminium profiles are versatile and used across various industries for framing, support, and structural applications.

L-Shaped Angles

Featuring two perpendicular legs (with equal or unequal sides), these are ideal for corner protection, shelving brackets, and structural reinforcement.

View Product

View Product

U-Channels/C-Channels

Characterized by a flat base with two parallel legs, these profiles serve as tracks for sliding systems, architectural lining, and lightweight framing.

View Product

View Product

T-Profiles

With a T-shaped cross-section, they are commonly used to join surfaces, create ceiling grids, or build modular frameworks where simple connections are needed.

View Product

View Product

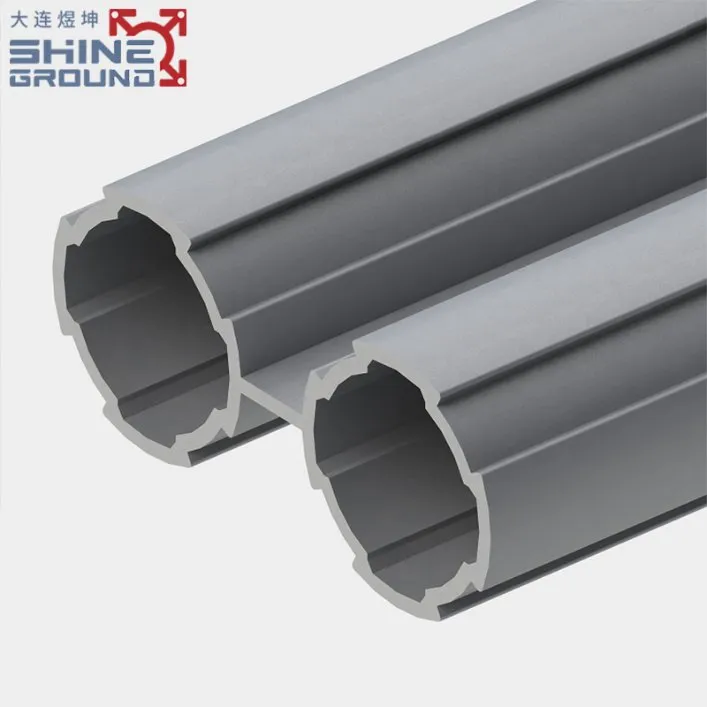

Hollow Tubes

Available in square, rectangular, or round sections, hollow tubes offer high strength-to-weight ratios. They are widely employed in machinery frames and handrails.

View Product

View Product

Bars/Rods

Solid profiles (flat, round, square, or hexagonal) function as reinforcements, spacers, axles, or decorative elements in machinery and construction.

View Product

View Product

I-Beams/H-Sections

Designed with a central web and flanges to resist bending, these are critical for load-bearing structures like bridges and heavy-duty equipment.

View Product

View Product

T-Slot and V-Slot Profiles

Modular T-slot extrusions are a specialized category enabling weld-free assembly. They feature grooves that accommodate T-nuts and bolts for adjustable, reusable structures.

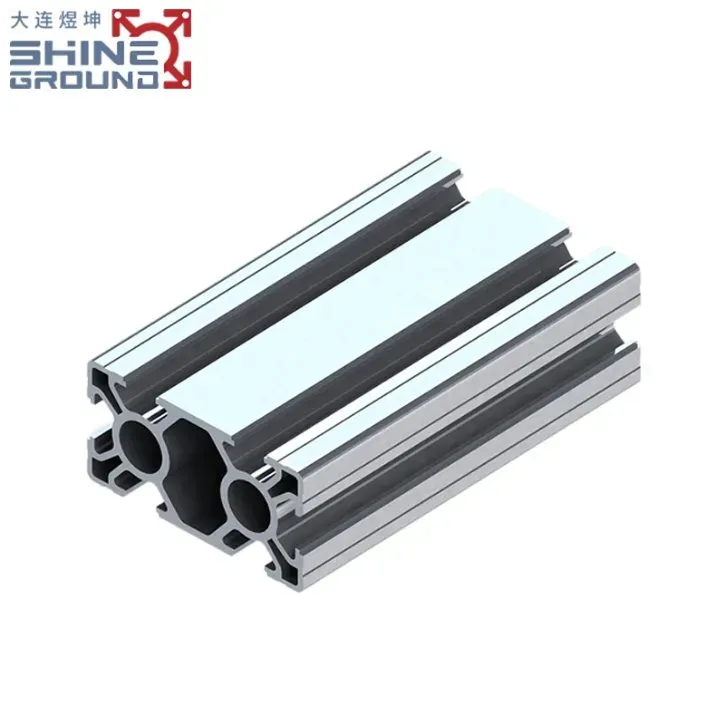

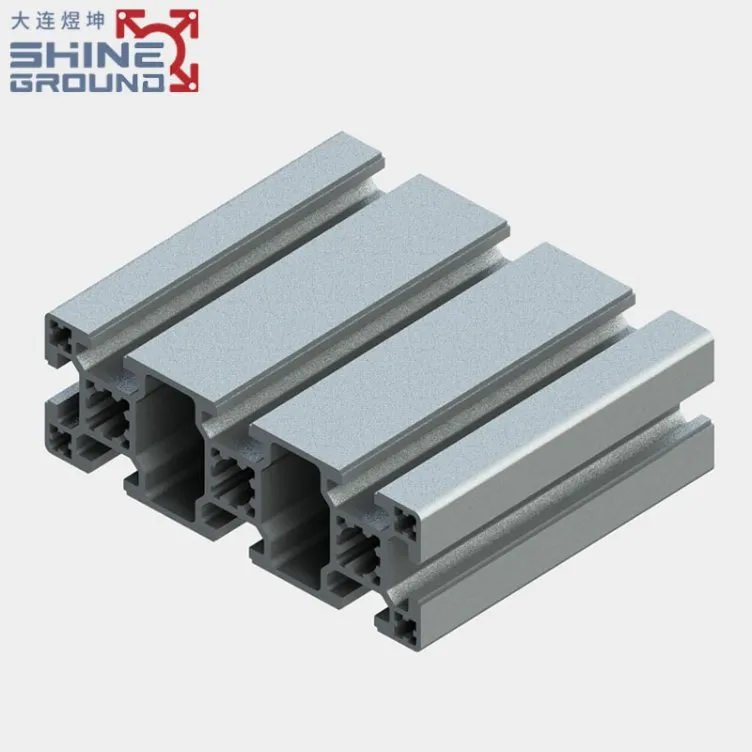

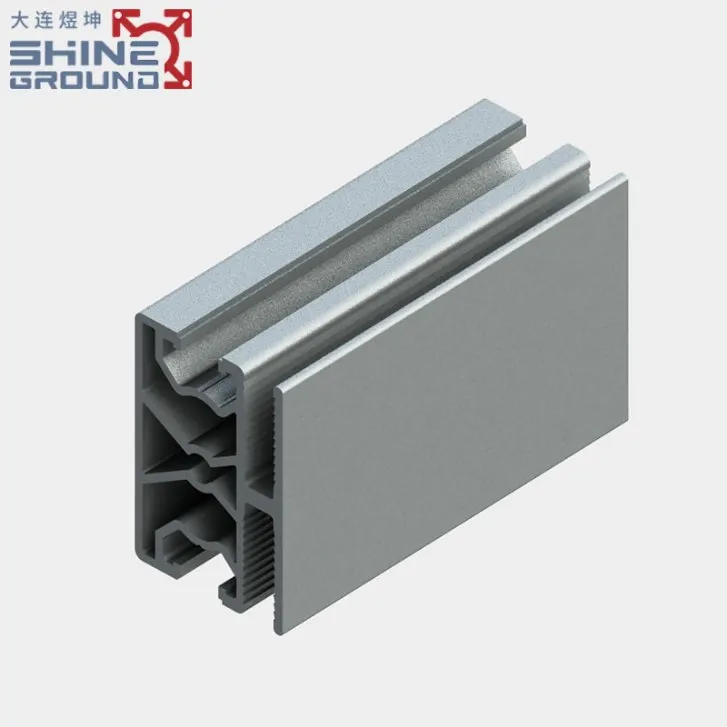

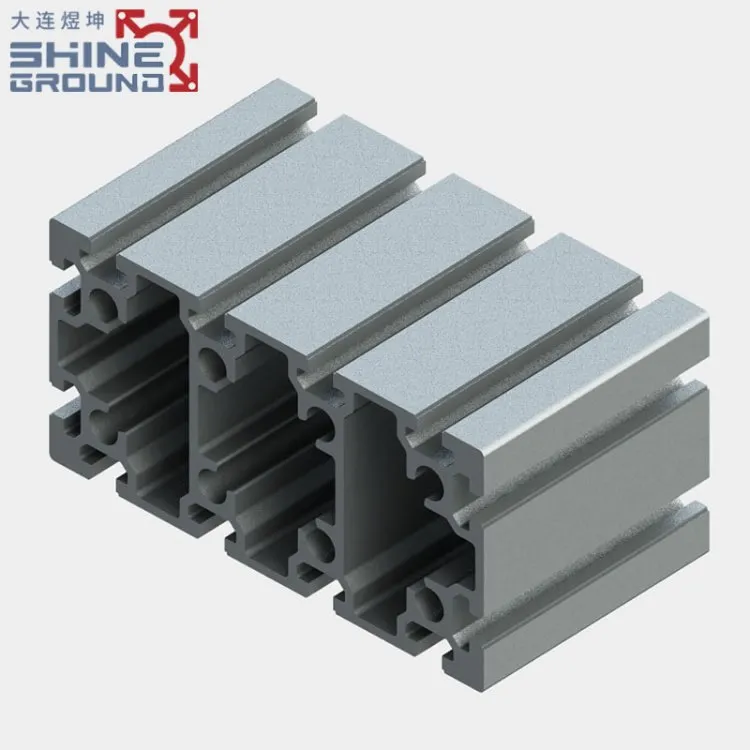

T-Slot Profiles

These allow flexible construction of machine frames, industrial workstations, safety guards, and automation equipment. Standard series (e.g., 20, 30, 40, 45) correspond to dimensions (e.g., 20×20 mm for light duty; 40×40 mm for industrial uses), ensuring compatibility with accessories.

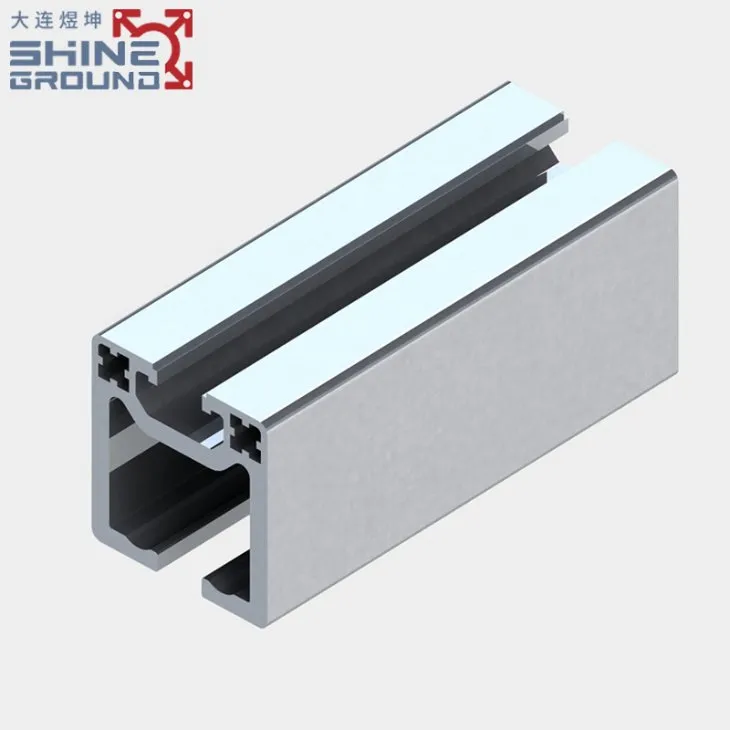

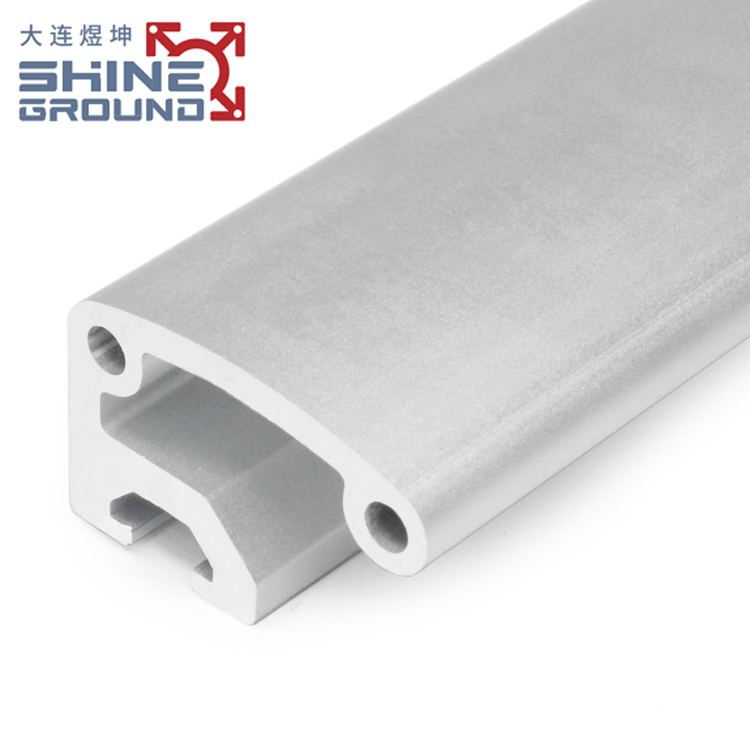

V-Slot Profiles

A variation with V-shaped grooves, designed for linear motion systems like 3D printers and CNC machinery, where wheels glide smoothly along the tracks.

Key Advantages

- Weld-free assembly

- Quick and easy to configure

- Reusable and reconfigurable

- Compatible with a wide range of accessories

- Ideal for custom machinery and automation

Key Application Industries

Standard aluminium profiles cater to diverse sectors due to their adaptability and performance.

Construction & Architecture

Used in window/door frames, curtain walls, solar panel mounts, and roofing. Their durability and aesthetic flexibility make them ideal for modern buildings.

Learn More

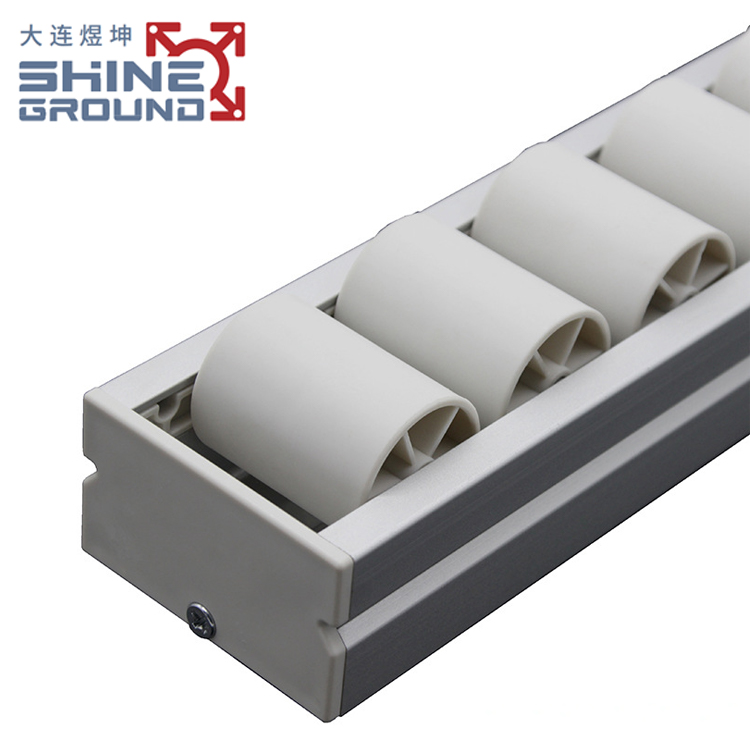

Manufacturing & Automation

T-slot systems dominate in machine bases, conveyor systems, and modular workstations, offering quick assembly and reconfiguration without welding.

Learn More

Transportation

In automotive, aerospace, and marine applications, aluminium profiles reduce weight while maintaining strength, improving fuel efficiency and payload capacity.

Learn More

Electronics

Heat sinks and equipment housings leverage aluminium’s thermal conductivity, while server racks benefit from its structural integrity.

Learn More

Furniture & Interior Design

From sleek furniture frames to office partitions, these profiles combine functionality with modern aesthetics.

Learn More

Renewable Energy

Used in solar panel frames, wind turbine components, and hydroelectric systems due to their corrosion resistance and lightweight properties.

Learn MoreAlloys and Quality Considerations

Understanding the right alloy and quality standards ensures optimal performance for your specific application.

Common Alloys

6063-T5

Offers excellent extrudability and a smooth surface for anodizing, suiting architectural applications where aesthetics are important.

6061-T6

Provides higher strength for load-bearing structures and applications requiring good machinability and weldability.

Alloy Comparison

| Alloy | Strength | Extrudability | Weldability | Common Uses |

|---|---|---|---|---|

| 6063-T5 | Medium | Excellent | Good | Architectural, frames |

| 6061-T6 | High | Good | Excellent | Structural, machinery |

Quality Considerations

Surface Quality

Avoid profiles with bubbles, cracks, or uneven coloring. High-quality profiles should have a smooth, consistent finish free from defects.

Wall Thickness

Main profiles for critical applications (e.g., exterior windows) should have a minimum wall thickness of 1.4mm to ensure structural integrity.

Protective Coatings

Standards like GB/T 5237 specify minimum coating thicknesses (e.g., anodized films ≥10µm, powder coatings ≥40µm) to enhance corrosion resistance.

Certification

Look for profiles certified to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management.

Ready to Start Your Project?

Discover the perfect aluminium profiles for your application and get expert advice from our team.

Contact Us

Have questions or need assistance? Our team is here to help you find the right aluminium profiles for your project.

Ask For A Quote Online

Fill out our online form to request a quote for your specific aluminium profile needs.

Get QuoteEmail Us

Send us an email with your questions or project requirements, and we’ll respond promptly.

Send EmailConnect with us directly on WhatsApp for immediate assistance and quick responses.

Message Us