Innovative Uses of Aluminum Profiles in Modern Industry

For decades, aluminum profiles have been the invisible backbone of modern industry, but recent technological advancements have unlocked revolutionary applications that are transforming everything from how we drive to how we build our homes.

Aluminum Profiles Market Overview

As factories increasingly seek smarter, greener, and more efficient material solutions, aluminum profiles have emerged as a critical enabler of innovation across diverse sectors. The following chart illustrates the distribution of aluminum profile applications across major industries:

Transportation

32%

Construction

28%

Industrial

22%

Renewable Energy

18%

Lightweighting the Future of Transportation

Electric Vehicle Revolution

The transportation sector is undergoing its most significant transformation in a century, and aluminum profiles are at the heart of this change. In electric vehicles, aluminum’s lightweight properties directly extend battery range—a critical competitive differentiator.

Every kilogram of weight saved through aluminum substitution improves energy efficiency by approximately 6-7%. Leading EV manufacturers like Tesla have embraced aluminum-intensive designs, with the Model Y utilizing aluminum die-cast components in its rear underbody to reduce part count by 79% while improving structural rigidity.

The innovation extends to battery enclosures, where high-pressure die-cast aluminum trays now constitute 18-25 kg per EV battery system, offering superior thermal management and crash protection compared to steel alternatives.

Aerospace Advancements

In the aerospace industry, where every gram matters for fuel efficiency, aluminum extrusions have become indispensable materials for aircraft and spacecraft manufacturing.

These specially designed profiles, produced through precision extrusion processes using carefully selected aluminum alloys (particularly 2000 and 7000 series), offer significant advantages including high strength, lightweight, and corrosion resistance while meeting stringent aerospace performance and safety standards.

The global market for aerospace aluminum extrusions is experiencing healthy growth, with revenue projected to reach $2,614 million by 2031, up from an estimated $1,774 million in 2024.

Transforming Industrial Automation and Manufacturing

Robotics and Advanced Machinery

Modern factories increasingly rely on modular T-slot aluminum profiles to construct rigid yet lightweight frames for robotic arms, work cells, and automated assembly lines. The versatility of these profiles enables quick reconfiguration of production lines without specialized tools, significantly reducing downtime during manufacturing process changes.

This modularity extends to custom workstations and safety enclosures, where aluminum profiles enable the rapid assembly of ergonomic, height-adjustable workbenches and machine guarding systems that protect workers while maintaining accessibility.

The precision manufacturing sector has particularly embraced aluminum profiles for building 3D printers and CNC machines. The dimensional accuracy and stability of aluminum extrusions make them ideal for creating the precise linear rails and frames required in these applications.

Sustainable Production Advantages

Beyond structural applications, aluminum profiles contribute to sustainable manufacturing practices through their recyclability. Aluminum retains nearly 95% of its original properties after recycling, and producing secondary aluminum consumes only 5% of the energy required for primary production.

High Recyclability

Aluminum retains 95% of its properties after recycling, enabling closed-loop material systems.

Energy Efficient

Secondary aluminum production uses only 5% of the energy required for primary production.

Cost Effective

Scrap buyback programs offset 15-20% of material costs while reducing environmental impact.

Redefining Architecture and Construction

Energy-Efficient Building Systems

In construction, aluminum profiles are revolutionizing building performance through advanced thermal break technology. These systems incorporate insulating materials that separate interior and exterior frame components, significantly reducing heat transfer and helping maintain comfortable indoor temperatures with less energy expenditure on heating and cooling systems.

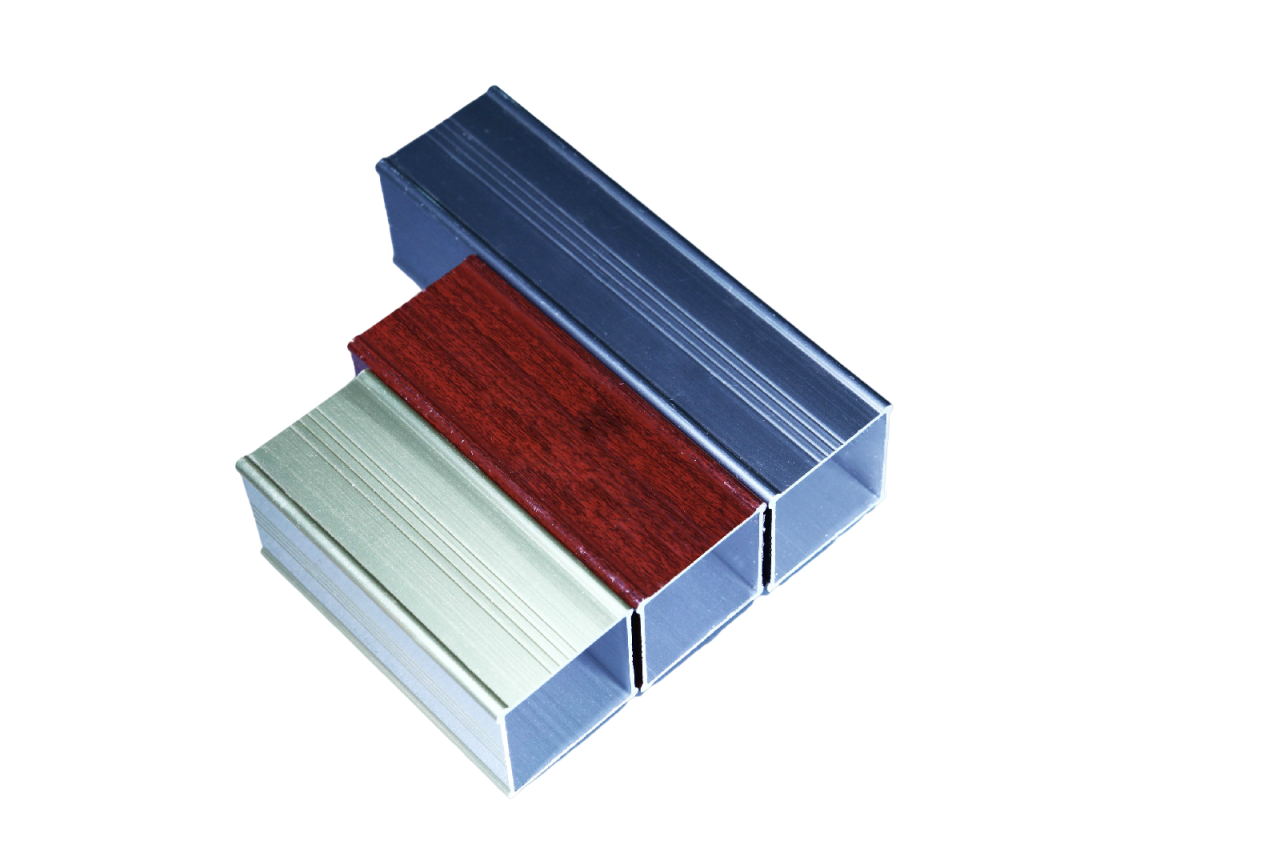

The 3D wood grain transfer printing technology developed by leading manufacturers allows aluminum profiles to mimic wood aesthetics while providing superior durability and weather resistance.

Smart building applications represent another frontier for aluminum profile innovation. Advanced framing systems now integrate embedded sensors to monitor structural integrity, temperature, and air quality, contributing to the development of intelligent, energy-efficient buildings.

Prefabrication and Modular Construction

The trend toward off-site manufacturing leverages aluminum’s lightweight and modular characteristics to create prefabricated building modules and panels that significantly reduce on-site construction time and costs.

This approach aligns with circular economy principles, as aluminum structures can be disassembled and repurposed at the end of a building’s life cycle. The durability and corrosion resistance of aluminum profiles ensure long service life even in challenging environments, with aluminum panels demonstrating 3-5 times better corrosion resistance than advanced high-strength steels.

Powering Renewable Energy and Electronics

Solar and Wind Energy Systems

In the renewable energy sector, aluminum profiles provide the durable, corrosion-resistant frames and mounting systems for solar panels and wind turbines. Their lightweight yet strong characteristics make them ideal for constructing solar panel frames and wind turbine components, allowing for easier transportation and installation while reducing costs.

The corrosion resistance of aluminum ensures that renewable energy infrastructure remains stable and functional for extended periods, even in harsh coastal environments.

The excellent thermal conductivity of aluminum profiles plays a crucial role in maintaining optimal operating temperatures for solar panels, thereby enhancing their performance and lifespan.

Advanced Thermal Management

Aluminum’s thermal conductivity (229-235 W/m·K) makes it indispensable for thermal management systems across multiple industries. In electric vehicles, liquid-cooled battery modules incorporate 6-9 kg of aluminum heat sinks and cooling plates per vehicle.

Porsche’s Taycan uses extruded aluminum profiles with microchannel designs that achieve 30% better heat dissipation than conventional copper alternatives.

The proliferation of 350 kW fast-charging infrastructure necessitates aluminum-rich thermal interfaces that can handle 400-600A currents without deformation.

Cooling system aluminum content is expected to grow 150% by 2028 as thermal management requirements become more demanding across electronics, energy storage, and power transmission applications.

Conclusion: The Future is Aluminum

As industries continue to prioritize efficiency, sustainability, and adaptability, aluminum profiles will play an increasingly critical role in enabling technological innovation. From transforming transportation through lightweighting to revolutionizing construction with smart building systems, aluminum’s unique combination of strength, lightness, corrosion resistance, and recyclability makes it uniquely positioned to address the complex challenges of modern industry.

For B2B partners seeking to stay ahead of market trends, understanding these innovative applications provides valuable insight into future demand patterns across sectors. As material science continues to advance, with developments in high-strength alloys and precision extrusion techniques, the potential applications for aluminum profiles will only expand, solidifying their status as a fundamental material shaping our industrial future.

Get in Touch

Looking to leverage innovative aluminum profile solutions for your industry? Contact our technical team to discuss how our advanced aluminum profiles can enhance your products and operations.

Ask For A Quote Online

Submit your inquiry through our online form and our team will get back to you promptly.

Learn MoreEmail Us

Send us an email with your specific requirements or questions about our aluminum profile solutions.

Send EmailConnect with us directly via WhatsApp for immediate assistance and quick responses to your queries.

Chat Now