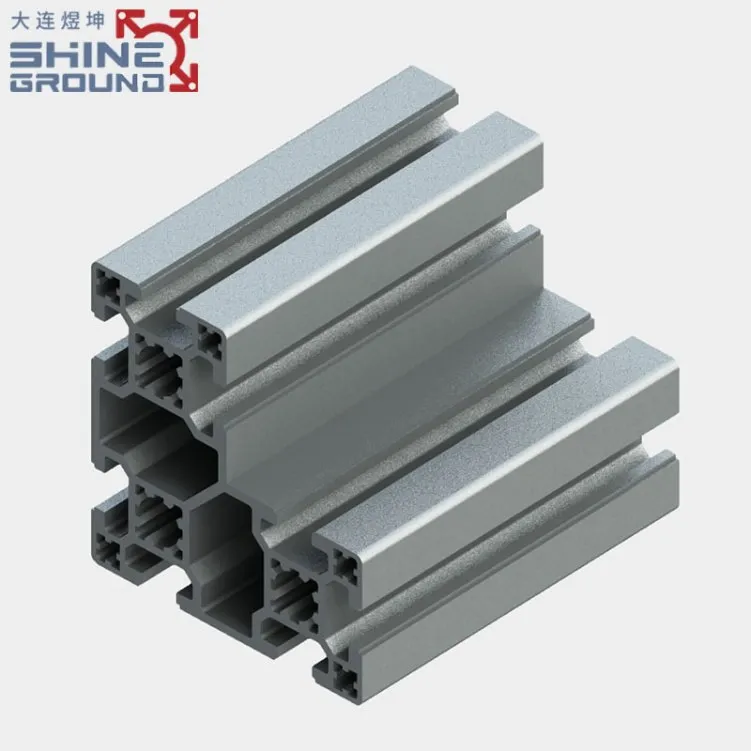

Anodized aluminum profiles have gained increasing popularity across Europe, not only for their durability but also for their compliance with strict industry standards and aesthetic demands. From automation equipment to architectural systems, European buyers consistently prefer anodized finishes for aluminum extrusions—and with good reason.

Enhanced Corrosion Resistance for Demanding Environments

European industries, especially those in Northern and coastal regions, operate in environments with high humidity or salt exposure. In these conditions, untreated aluminum can degrade quickly. Anodized aluminum, however, forms a hard, non-reactive oxide layer that offers excellent resistance to corrosion.

A report from the European Aluminium Association shows that anodized finishes can extend the lifespan of structural components by 30%–50%, making them ideal for long-term installations such as machine frames, cleanroom partitions, and outdoor solar structures.

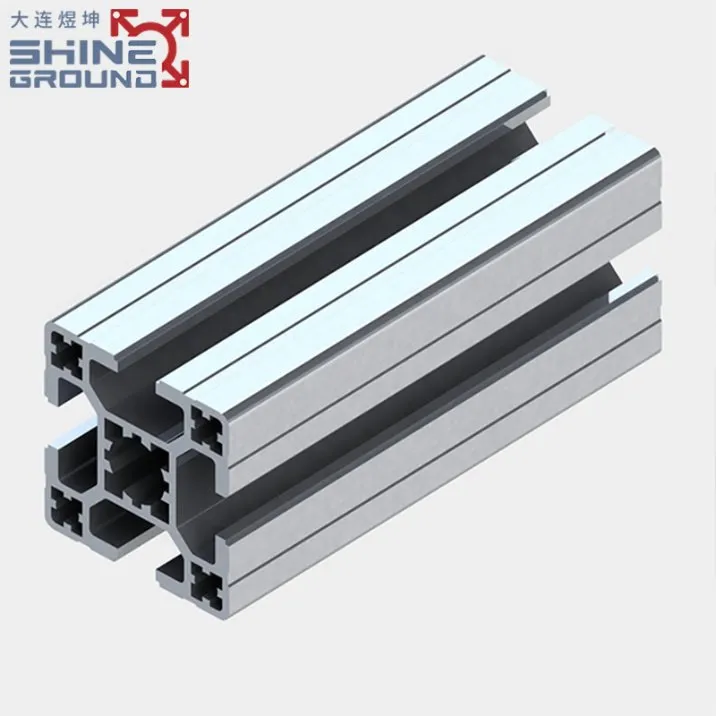

Aesthetic Consistency for Architectural and Technical Use

European markets often demand a polished and professional look—whether for retail displays in Germany, cleanroom systems in the Netherlands, or façade structures in France. Anodizing creates a uniform, high-quality surface finish with a natural metallic sheen that resists fading and discoloration.

Unlike powder coating or paint, anodizing doesn’t peel or chip. Clients also value the availability of multiple finishes—silver, black, bronze—that match both industrial and architectural design expectations.

A German automation client, for example, reported a 25% reduction in quality complaints after switching to anodized aluminum profiles for their control enclosures, citing better surface consistency and improved brand image.

Alignment with European Sustainability Standards

Sustainability is not a trend in Europe—it’s a requirement. Regulations like RoHS and REACH, as well as client CSR policies, place pressure on manufacturers to adopt low-impact, non-toxic materials.

Anodizing fits perfectly within this framework. It’s a water-based, VOC-free process, and the anodized layer is 100% recyclable. Compared to painting or plating, the environmental footprint is significantly lower, which aligns with EU clients’ procurement policies.

Many clients also ask for anodizing certification data. At Shine Ground, we provide detailed surface reports that document coating thickness and salt-spray test results, which helps clients meet audit requirements from end-users in sectors like medical devices or electronics.

Dimensional Stability for Precision Assemblies

European engineering projects often involve strict tolerances. One of the key advantages of anodizing is that it forms a surface layer without distorting dimensions—no buildup, no shrinkage.

For example, a Danish equipment integrator building laboratory automation systems chose anodized 40×40 T-slot profiles with a 15μm finish. Their mechanical engineer noted that “the anodizing layer kept tolerances within ±0.05mm across the entire batch,” which was critical for sensor alignment in high-speed conveyor lines.

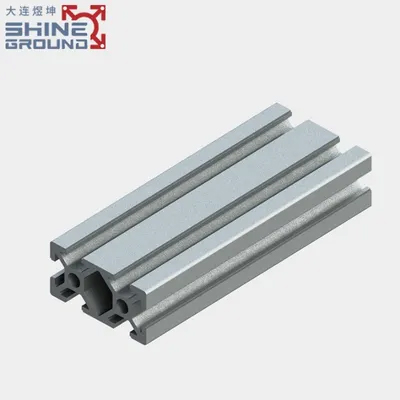

Long-Term Value and Batch Consistency

Cost-conscious European buyers still care about one thing above all: value over time. Anodized aluminum offers exceptional lifecycle performance, with minimal maintenance and replacement needs. Unlike coatings that wear off or chip, anodized surfaces remain intact even after frequent handling or cleaning.

From a supply chain perspective, anodizing also ensures consistency across production runs. European clients working with multiple modules or prefabricated sections need matching surface tone and performance across large volumes—something untreated or powder-coated aluminum can’t always guarantee.

Our clients in Belgium and Sweden have praised Shine Ground for delivering 100% finish consistency across multi-ton shipments—a critical requirement for warehouse automation and packaging system projects.

For European buyers, anodized aluminum profiles are more than a visual upgrade—they’re a strategic choice. With better corrosion resistance, eco-compliance, dimensional precision, and aesthetic consistency, anodized finishes meet the high standards of Europe’s most advanced industries.

If you’re sourcing aluminum profiles for EU markets, choosing anodized options from a trusted supplier like Shine Ground can enhance both product quality and customer satisfaction.