How to Connect Aluminium Profiles

A comprehensive guide for B2B buyers on selecting the right connection methods for structural integrity, aesthetics, and functionality.

Why Connection Methods Matter

Structural Stability

The right connection method ensures optimal load-bearing capacity and structural integrity for your aluminum frameworks.

Ease of Assembly

Connection methods determine how easily your structures can be assembled, disassembled, and modified as needed.

Aesthetic Appeal

Hidden or visible connections significantly impact the visual appearance of your final product.

Flexibility

Connection choices affect how easily your structures can be modified or repaired in the future.

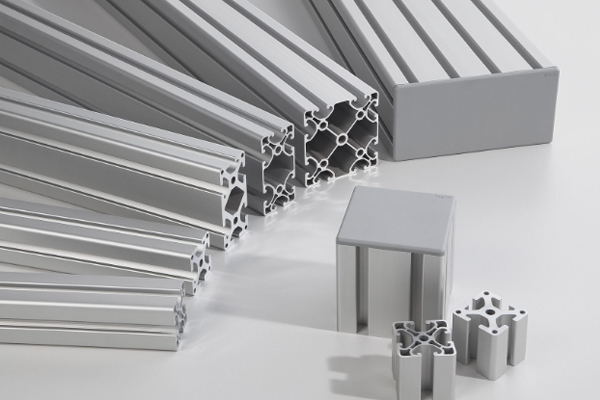

Primary Connection Methods

Explore the various techniques for connecting aluminum profiles, each offering unique advantages for different applications and requirements.

Internal Connectors (Hidden Connections)

Internal connectors provide a clean, professional appearance as they’re concealed within the profile slots. These methods typically require some machining but offer superior aesthetics.

Built-in Connectors

Used for 90° connections between two profiles, providing hidden connections with high strength.

Learn more

Anchor Connectors

Offer versatile options for connecting two profiles at various angles while remaining hidden from view.

Learn more

One-Piece Connectors

Enable direct end-to-end joining of profiles, essential for creating longer spans from multiple profile sections.

Learn moreExternal Connectors (Visible Connections)

External connectors offer easier installation and adjustability, making them ideal for applications where aesthetics are less critical or where frequent modifications are anticipated.

Angle Brackets/Gussets

L-shaped components that use T-nuts and bolts to secure two profiles, typically at 90-degree angles. These brackets come in various configurations including 90°, 45°, and 135° options.

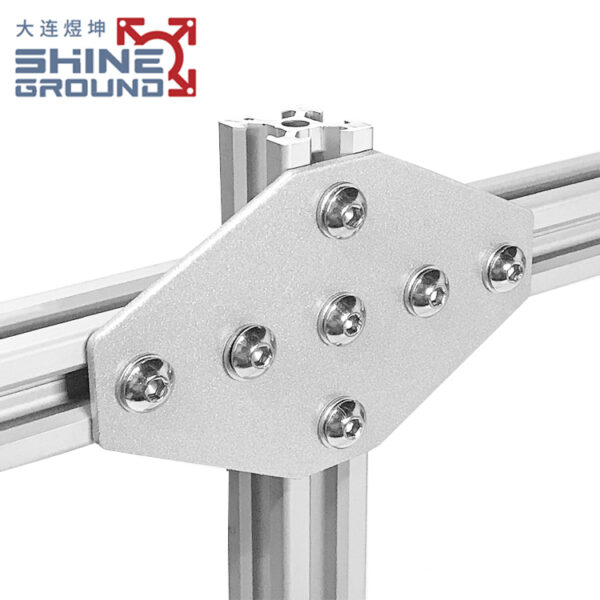

Connection Plates

Including L-shaped, T-shaped, and Y-shaped variants used for interconnecting multiple profiles in various configurations.

Specialized Connection Systems

For specific applications, more specialized connection methods offer unique advantages to meet particular design requirements.

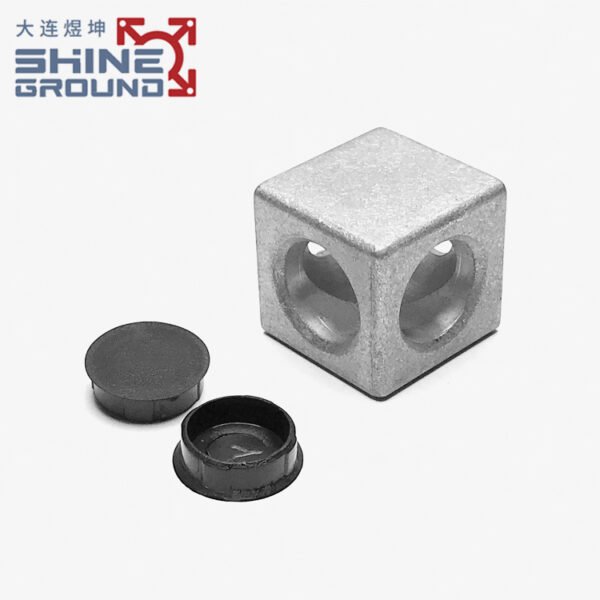

Three-Dimensional Connectors

Facilitate complex joints where three profiles meet at right angles or with rounded corners.

Learn more

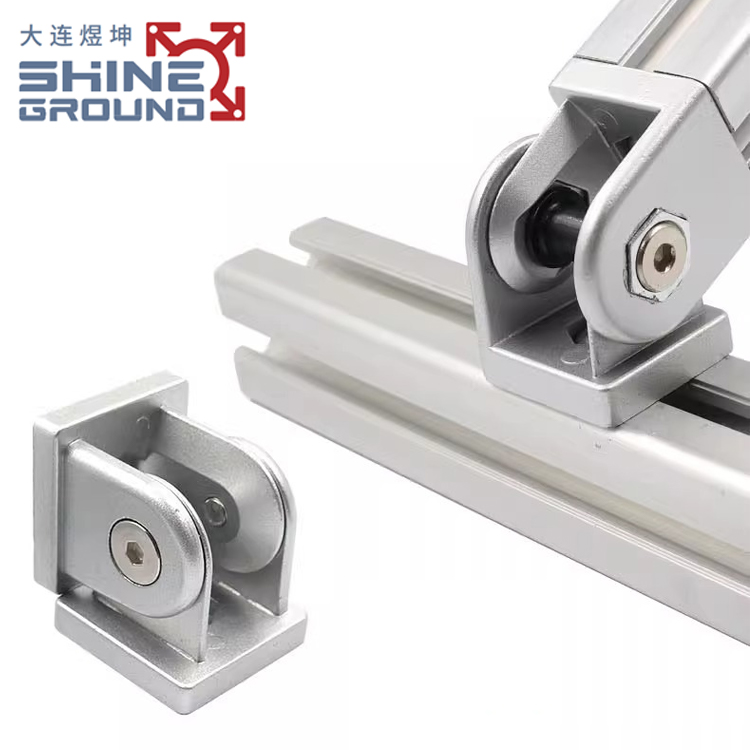

Adjustable Hinges

Allow connections between profiles at variable angles (typically 30°-150°) for flexible designs.

Learn more

Elastic Fasteners

Provide efficient 90° internal connections that can be easily installed and removed as needed.

Learn moreKey Considerations When Selecting Connection Methods

Load Requirements and Structural Demands

The anticipated loads and stress factors your structure will face should dictate your connection choice. For heavy-duty applications, gussets, multiple brackets, or through-bolt connections with proper reinforcement are essential. Lighter applications may be well-served by simpler internal connectors.

Aesthetic Priorities

When visual appeal is crucial, hidden internal connectors provide the cleanest appearance. For industrial applications where looks are secondary, external brackets offer practical advantages without compromising function.

Flexibility and Future Modifications

If your application requires frequent adjustments or potential disassembly, T-nut based systems or drop-in connectors offer the greatest flexibility. For permanent installations, fixed connections with screws or specialized brackets may be preferable.

Installation Constraints

Consider the tools, expertise, and time available for assembly. Some methods require specialized drilling jigs or tapping equipment, while others can be assembled with basic hand tools.

Advanced Connection Techniques

Thermal Joining Methods

While mechanical fastening is most common for aluminium profiles, advanced welding techniques have emerged for specialized applications. Recent developments in nanoparticle-enabled welding have made it possible to join previously “unweldable” high-strength aluminium alloys like AA 7075.

This technology infuses carbonitride nanoparticles into the weld filler material, creating joints with tensile strengths up to 392 megapascals (increasing to 551 MPa after heat treatment)—comparable to steel joints.

Combined Approaches

In many industrial applications, combining multiple connection methods yields optimal results. For example, using both internal connectors for alignment and external brackets for added strength can create structures that benefit from both approaches’ advantages.

This hybrid approach is particularly valuable in applications where both aesthetic appeal and maximum structural integrity are required.

Practical Applications Across Industries

Automation Equipment

Often benefits from rigid, vibration-resistant connections to ensure stable operation of precision machinery.

Display Systems

Typically prioritize quick assembly and aesthetic cleanliness to create attractive retail environments.

Material Handling

Requires robust connections capable of withstanding dynamic loads in conveyor systems and storage solutions.

Architectural Applications

Need connections that balance strength with visual appeal for interior and exterior building elements.

Need Expert Advice?

Our technical support team can help you select the optimal connection methods for your specific applications. Contact us today for personalized recommendations.